How is the handling of motors during their manufacture in practice?

Motors come in countless shapes, sizes, weights and designs. This makes handling a challenge. Many motor manufacturers plan threaded holes at the design stage, into which either screwable lifting points or simple eyebolts are then inserted during the manufacturing process. Other engine manufacturers provide their components with permanently welded lifting points which then remain on the engine permanently. A variant that is not yet very common is handling with so-called plug-in lifting points. When handling motors with screw-on lifting points or eyebolts, the lifting points must be screwed into the respective threaded holes by hand and checked for tightness. Depending on the number per motor, this may take some time. If the lifting point is then not to remain permanently on the motor, it must be unscrewed from the threaded hole again after the lifting process. Depending on the application, various lifting points are possible solutions.

Plug-in attachment points for handling motors

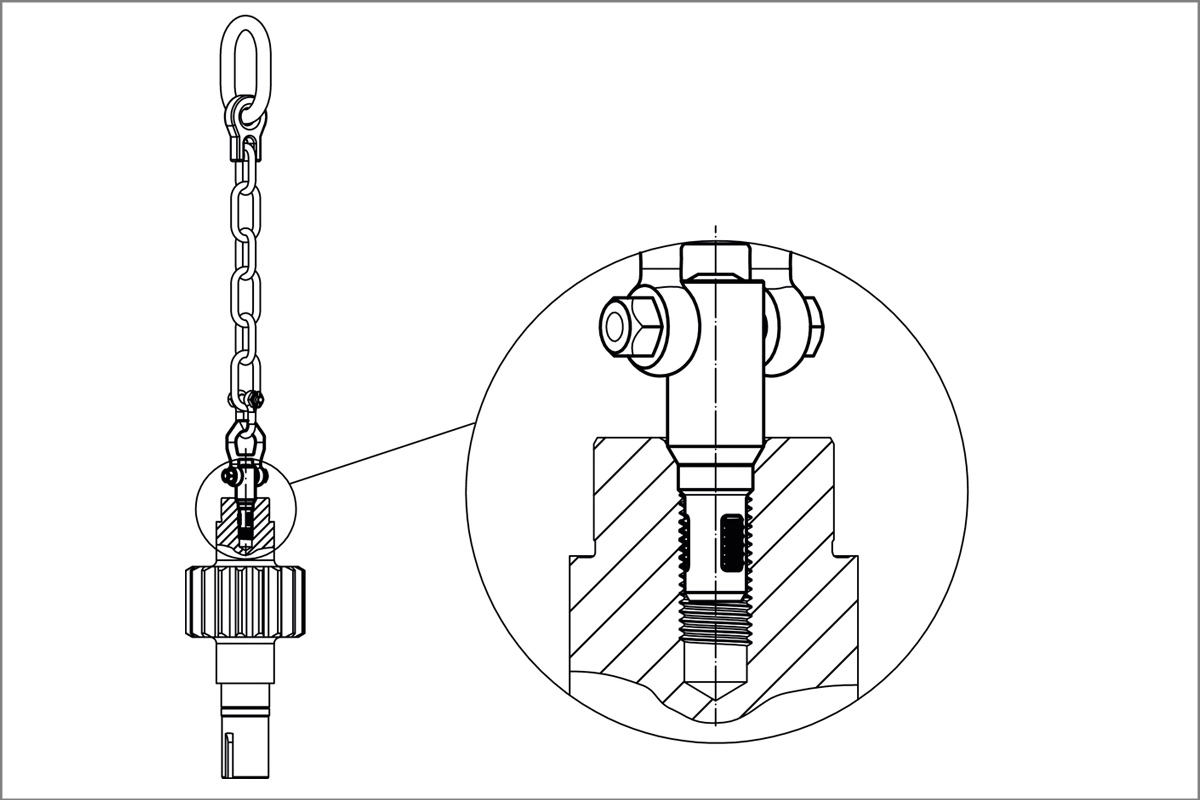

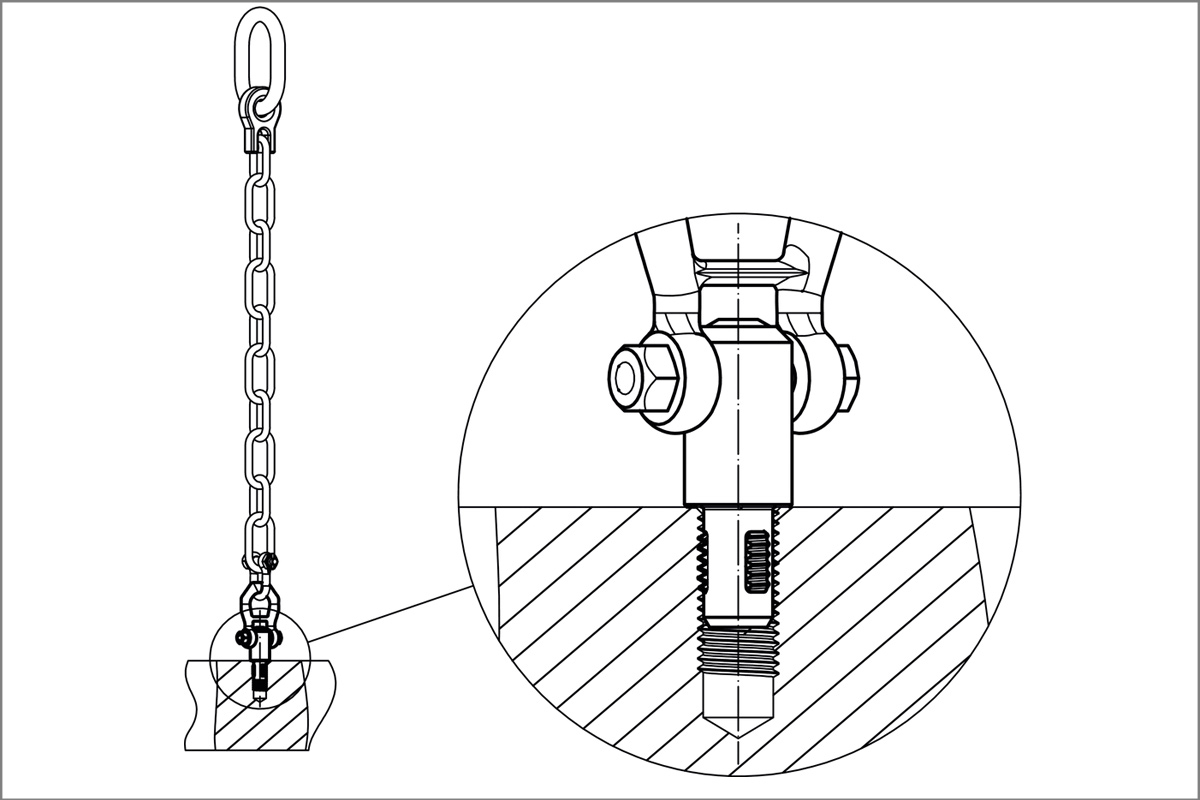

The particular advantage of plug-in anchor points is that plug-in anchor points are not, as the name suggests, screwed in, but rather plugged in. In practice, this saves the user a considerable amount of time. Instead of a thread, this anchor point uses a threaded lifting pin. This means that the anchor point can be quickly and easily inserted into an existing, suitable threaded hole. The shape of the anchor point includes a safety device to prevent unintentional release from the load. However, it should be noted that ball suspension bolts are not suitable for continuous rotation of the load and dirt can quickly impair the function of the ball suspension bolts.

In a recent case, the customer wanted to significantly reduce the assembly time in the production of its motors for fans, while maintaining safety during the lifting process at all costs. The customer approached the Carl Stahl expert consultant with his requirements. The solution: threaded lifting pins from Erwin Halder. Depending on the application, the threaded lifting pins are available in “self-locking” and “self-locking with rotating shackle” versions.

The advantages of plug-in anchor points from Erwin Halder

- Existing threads can be used

- Self-locking - unintentional loosening of the load is therefore impossible

- Enormous time saving as screwing and unscrewing is no longer necessary

- No damage to the surface of the load (possibly already painted, etc.)

- Ideal for lifting shafts with centering holes

Buy plug-in lifting points

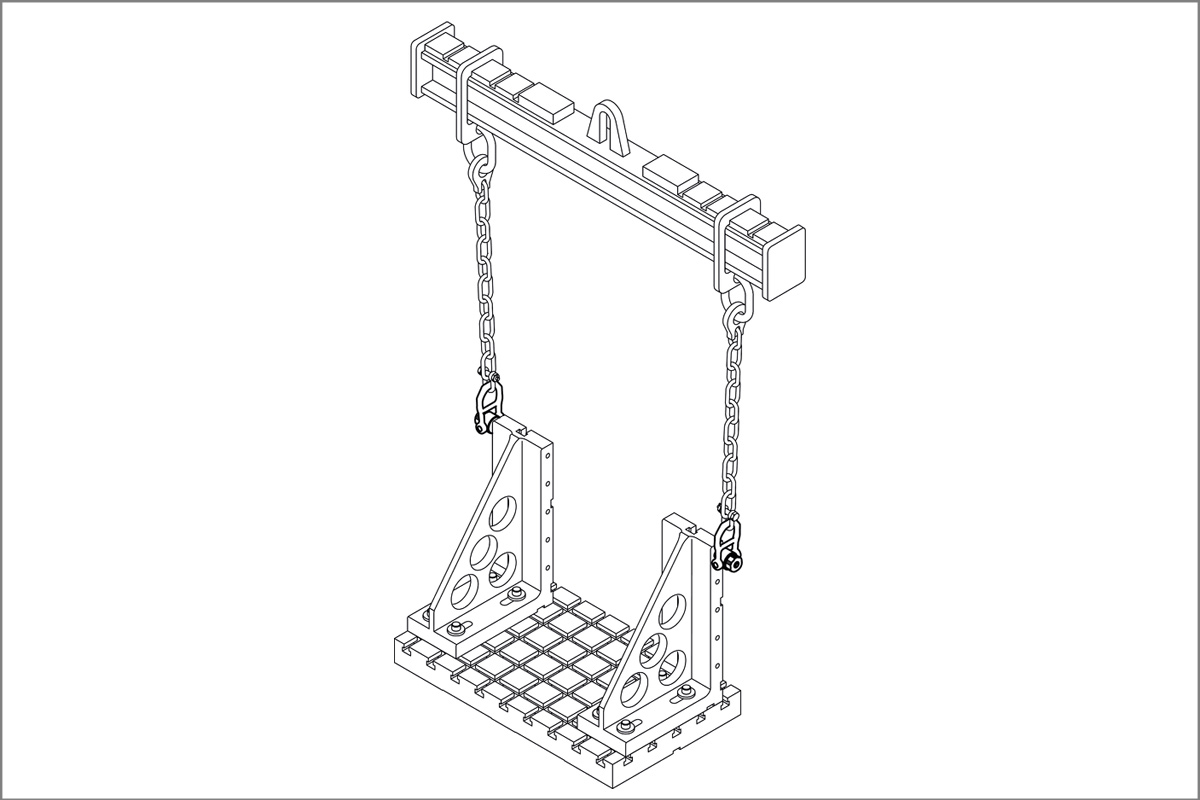

Application examples for plug-in anchor points from Erwin Halder:

Threaded studs Erwin Halder - Product presentation

Threaded lifting pins Erwin Halder - The innovation in the lifting equipment sector | Carl Stahl GmbH

Buy plug-in lifting points

FAQ: Handling motors with plug-in lifting points

Are there plug-in lifting points for all load capacities?

Unfortunately not. The available load capacities are currently between 0.4 and 3 tons, depending on the version.

How do the plug-in anchor points compare in terms of price to eyebolts or screw-on lifting points?

The slightly higher price of plug-in anchor points compared to classic eyebolts or screwable lifting points is more than compensated for by the time saved.

Are Erwin Halder's plug-in lifting points also approved for transporting people?

No, plug-in lifting points from Erwin Halder are only approved for lifting and holding individual loads. Special lifting points are available for use as fall protection in the area of PPE.