What is an injection molding machine?

An injection molding machine (also known as an injection molding machine) is a machine that produces plastic parts from plastic in the form of granulate or powder. For this purpose, the required molding compound is prepared in the so-called injection unit and injected into a die, which represents a negative mold of the desired plastic part. Depending on the process used, various components of the machine are heated or tempered. Injection molding machines basically consist of two assemblies: The injection unit or plasticizing unit, which prepares the raw material and injects it under pressure into the tool (also known as the mould), and the clamping unit, which holds the tool and opens and closes it.

Why do you need handling devices on injection molding machines?

Basically, you might think that plastic parts can't be that heavy. That is certainly true for the most part. But injection molding machines can easily be several meters in size. The parts they produce are correspondingly large and heavy. And even low weights can quickly lead to tension and incorrect strain on the body when working continuously. Unfortunately, this often results in long-term illnesses. Therefore, prevention is the best protection for the long-term health of the worker at the machine. Depending on the size of the injection molded part and the cycle time, several kilos can quickly add up per day. If it is then necessary to twist the body, for example to remove the finished parts from the machine and place them in a box, additional strain is placed on the musculoskeletal structure. In addition to the weight, the shape and temperature of the manufactured component can also have an impact on handling. Large-format, sharp-edged components with an off-center center of gravity and still hot (warm) from production affect handling.

The advantages for the operator are

- Satisfaction due to an ergonomic workplace

Safe and ergonomic lifting and moving of loads

Effortless and precise positioning of loads

Uncomplicated and fast transportation of awkward loads

High level of safety for people and loads

The handling of components on a customer's injection molding machine

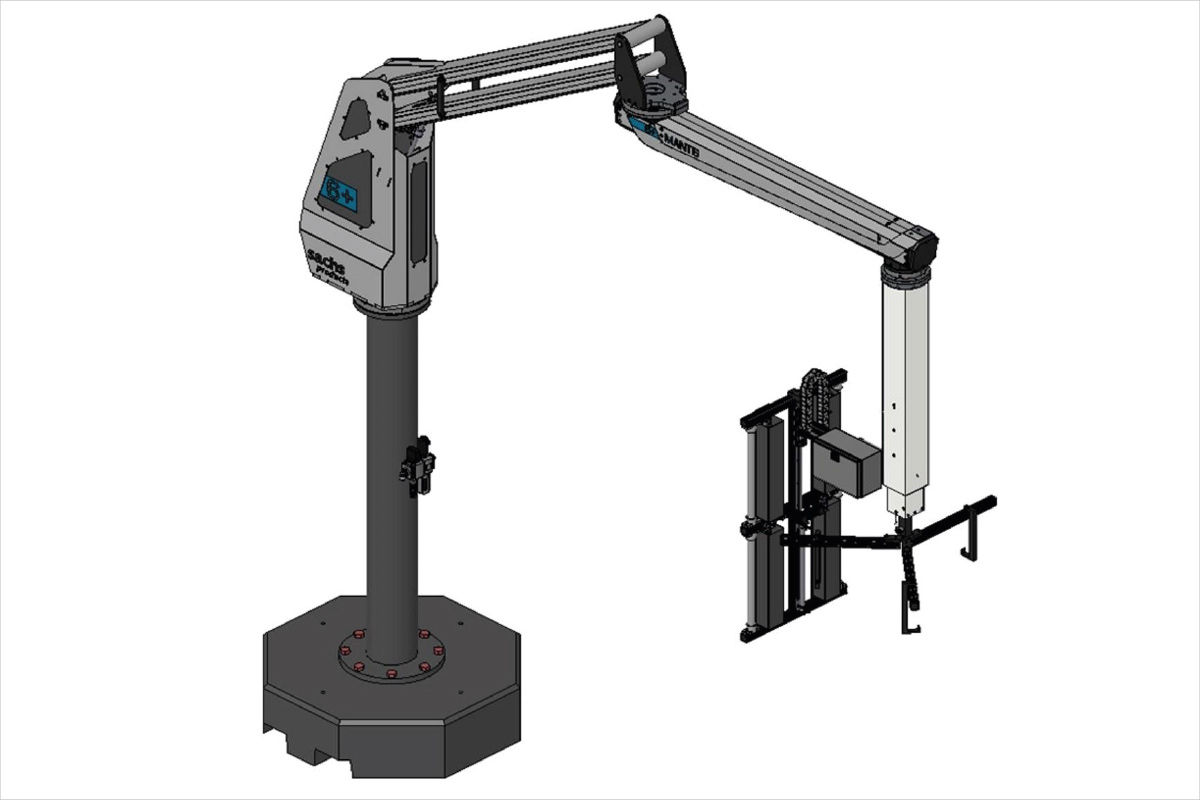

A customer produces different types of plastic parts on his injection molding machine. These plastic parts have to be transferred from a roller conveyor on the ejection side of the machine. Due to the high number of parts and to support the employee at the machine, a so-called manipulator was suggested after a detailed analysis of the work area. Due to the changing work area, this should be mobile. The workstation solution is a mobile, electro/pneumatic parallel arm manipulator of the MANTIS type from Sachs. It is equipped with a mechanical gripper and a vacuum lifter. The MANTIS has a unique selling point compared to other competitor products on the market thanks to its integrated scales. Regular manual adjustment depending on the load weight at a compressed air valve is not necessary with the electronic scale of the MANTIS.

What are the advantages of the MANTIS parallel arm manipulator?

- No need for regular readjustment of the pneumatic support by the electronic scale

Quick-change load handling attachments

Silent generation of the vacuum thanks to the use of a Venturi nozzle

Mobile, so can be used at several workstations

Technical data:

- Exclusively pneumatic

Maximum operating pressure of 6 bar (87 psi)

Up to 3600 mm (11.8 ft) working radius as standard

Up to 1800 mm (5.9 ft) working stroke, infinitely adjustable

Three compressed air circuits: one control circuit, one working circuit, one brake circuit

Overpressure safety valve adjustable to user-specific pressure

Maximum load capacity up to 400 kg (880 lbs)

Integral design

Light operating forces

FAQ: Manipulator with mechanical gripper and vacuum lifter

Are there other options for handling components on injection molding machines?

Depending on the analysis and evaluation of the work area, an exoskeleton could also facilitate the handling of injection molded parts.

Can the MANTIS parallel arm manipulator also grip other components?

Of course. The MANTIS has a wide range of connection options for load handling devices for handling different loads.

Are there other safety risks that need to be considered on an injection molding machine?

There are indeed. For example, when changing the injection mold or during maintenance work, workers can get into an area where there is a risk of falling when climbing onto the machine. This makes it necessary to use appropriate protective equipment.