Many steel traders know this situation all too well: the delivered material has different dimensions and weights. Nevertheless, the steel plates or steel packages must be unloaded from or loaded onto the truck quickly without jeopardizing the safety of the slinger or even damaging the material. Once the steel plates have been unloaded, they are stored or transferred within the internal logistics system. Due to the many material variants, handling with a standard lifting beams is almost impossible. Traditionally, conventional lifting gear or lifting magnets are often used. However, not enough attention is often paid to the sharp edge on the load. This can damage the lifting points and, in the worst case, lead to a safety risk or a load falling. To ensure that materials are still moved safely, ergonomically and efficiently within a value chain, customized workstation solutions are always preferable to standard variants.

The customer has to transport steel plates and packages within its value chain. This begins with loading and unloading onto and from the truck and ends with storage and relocation. During the transportation process, up to 3 steel packages with a total load of 7.5 t (16,535 lbs) have to be moved, with the steel packages measuring between 2 m and 4 m in length (6.6 ft and 13.1 ft), between 1 m and 1.6 m in width (3.3 ft and 5.2 ft), and between 0.7 and 1 m in height (2.3 ft and 3.3 ft). In addition, all steel plates are very sharp-edged and have no attachment points where the plates could be moved with a sling, for example.

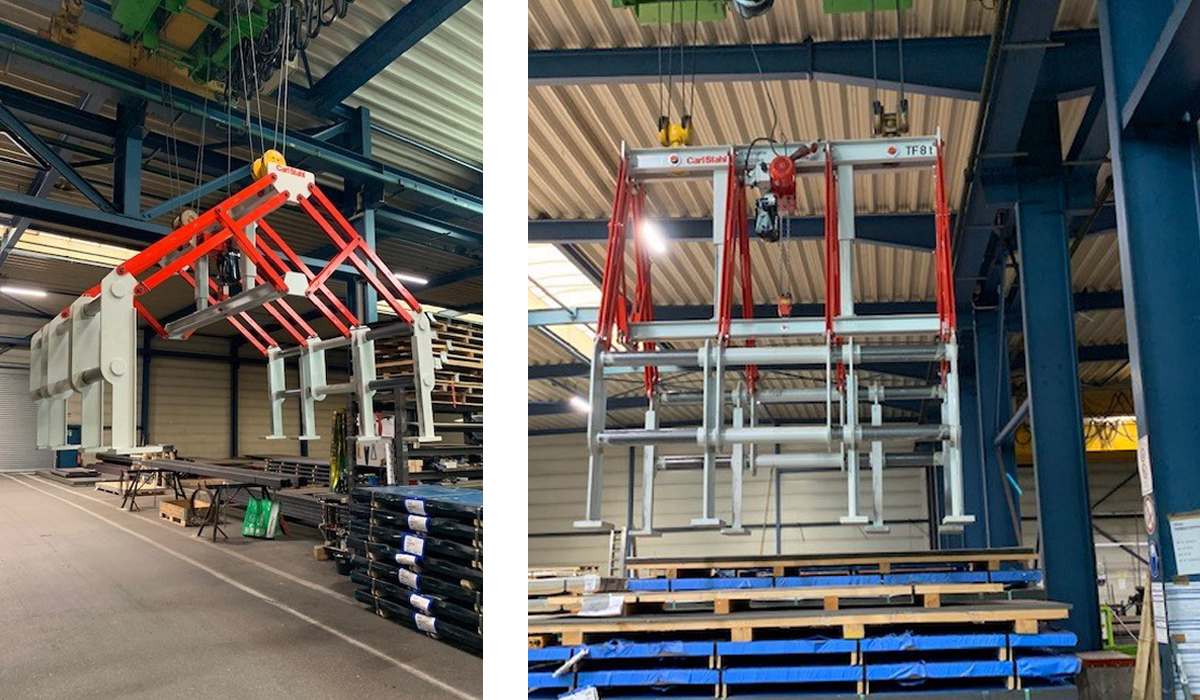

Due to the different parameters, Carl Stahl developed and manufactured a special grab that can be adjusted in length and width and has a maximum load (load capacity) of 8 tons (17,637 lbs). A special feature of this special grab is that an integrated electric chain hoist from HADEF with a load capacity of 1 t (2,205 lbs) can be controlled via the crane hook block and is used to open and close the grab. Carl Stahl has decades of experience in the design and production of customized special load handling attachments. Carl Stahl manufactures its load handling attachments at 4 locations in Germany on an area of around 1,250 square meters (13,455 sq ft). Consistently high quality is ensured by certified processes and trained skilled workers.

Steel plates can also be attached in the following ways: