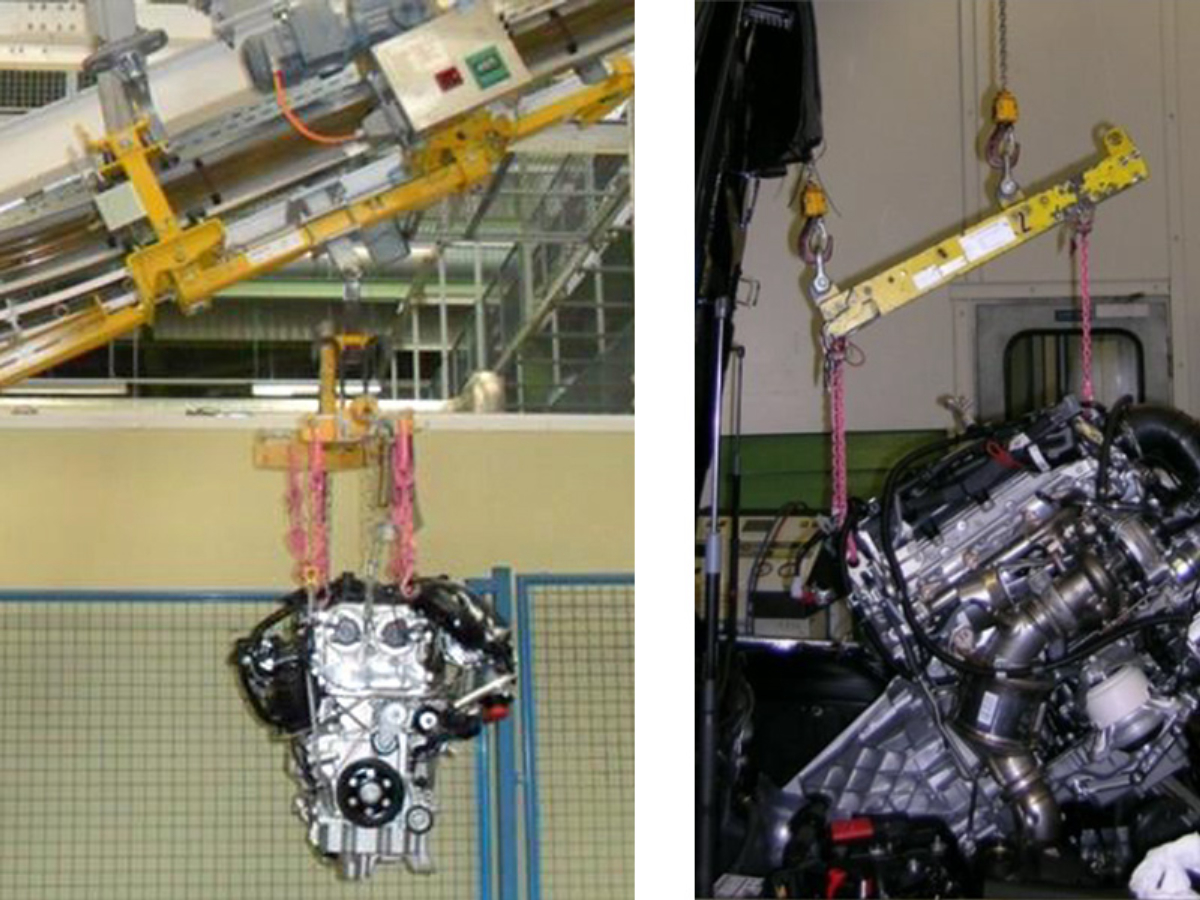

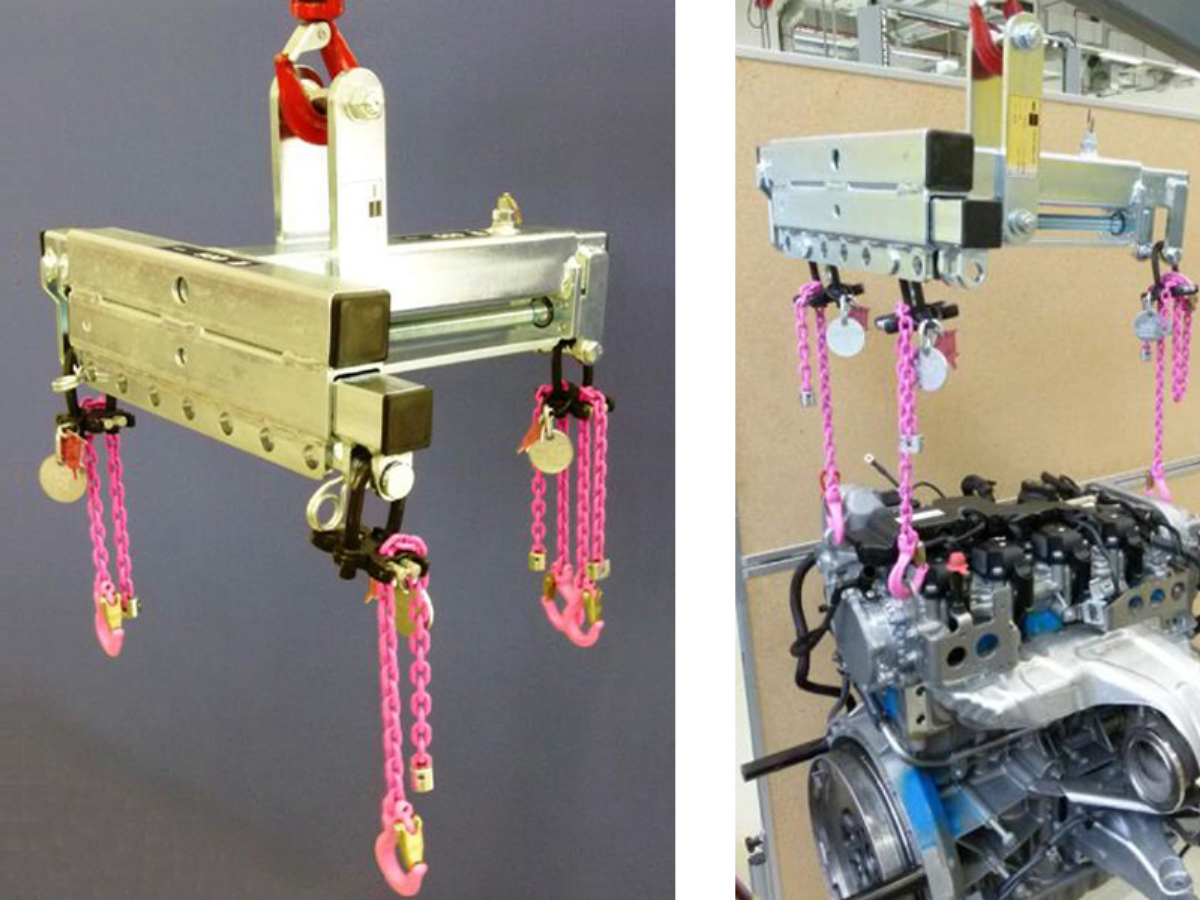

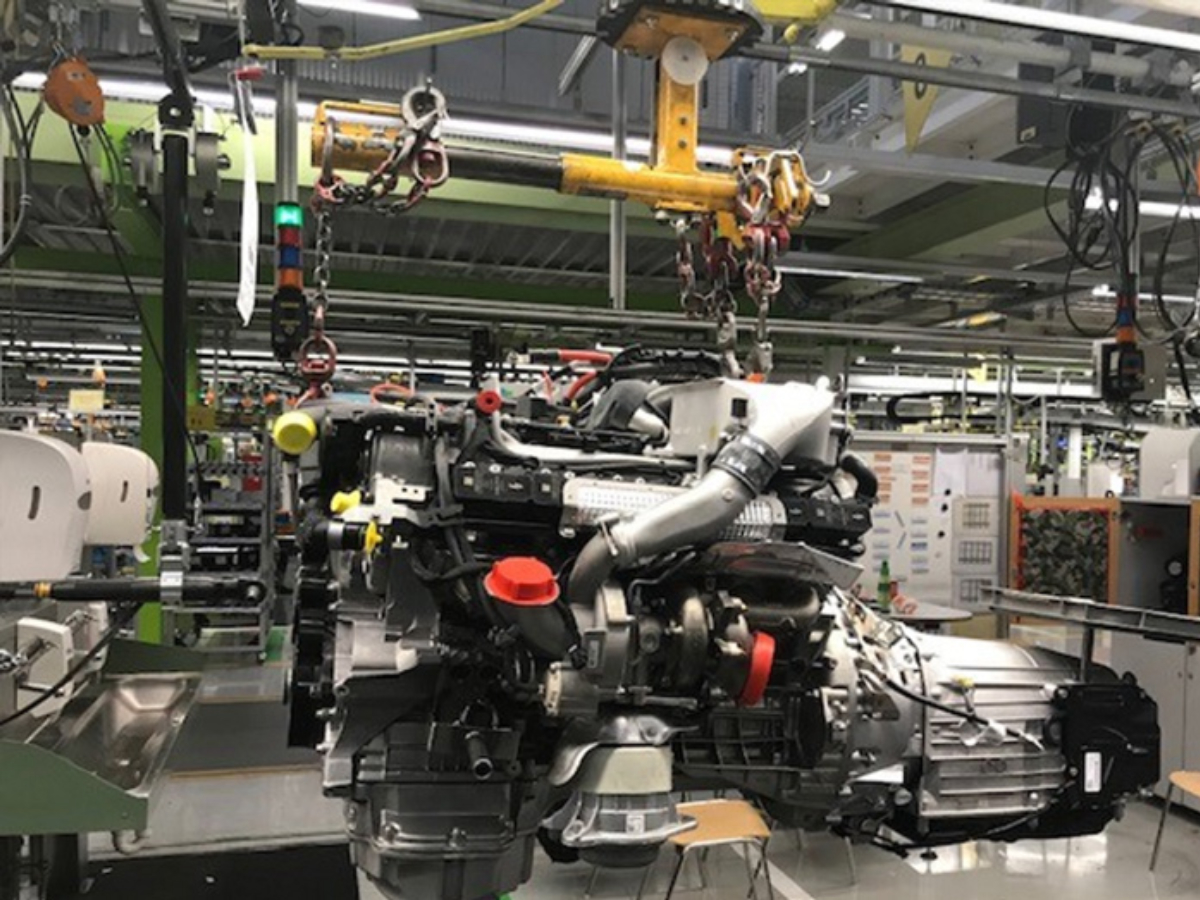

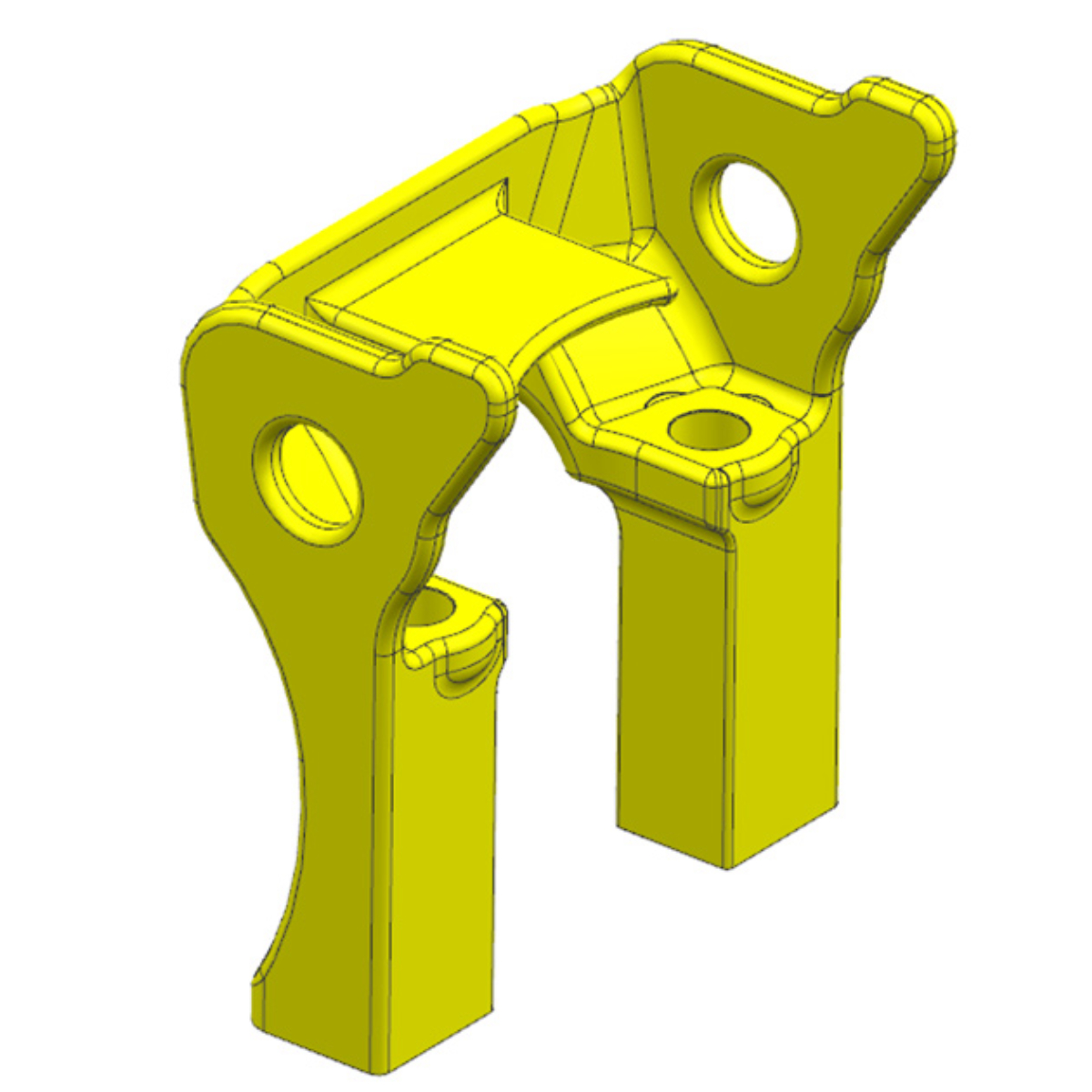

The engine selection is just as varied as the vehicle range of a car manufacturer. Each engine has its own dimensions, centre of gravity, shape and weight. To ensure safe handling of each unit, it must be possible to transport the engine absolutely safely and horizontally. Due to the variety of engines from each car manufacturer, it is difficult to fall back on standard load handling equipment. Customised equipment is therefore almost always necessary for these applications. Mercedes AMG GmbH also faced this challenge when looking for a suitable solution for handling the M279 engine. However, Mercedes was unsure how to classify and standardise the special solution and how the component had to be designed. The solution for engine handling consists of an upper suspension eye that is mounted on the engine so that it can be moved safely during in-house transport. The upper suspension eye is also required in customer service workshops to remove the engine from the vehicle. In addition to the upper suspension eyelet, the engine has a further suspension eyelet on the control cover. Overall, the engine is thus securely attached at several points simultaneously with the help of a load cross member and attachment chains.

After consultation with the Carl Stahl expert consultation, it was determined that the suspension eye should be a load suspension equipment or at least a lifting point. In order to specify this precisely, Carl Stahl was commissioned by Mercedes-AMG GmbH to assist with the creation of a specification sheet. Firstly, Carl Stahl worked out what the requirements of the Machinery Directive are with regard to the design requirements for a load handling attachment. Next, the requirements placed on a manufacturer and, in the final step, the requirements for legally compliant documentation. In addition, Carl Stahl developed a prototype proposal. All this information was used to create a specification sheet, which later became the basis for a tender. The suspension eye is permanently labelled with the internal equipment number and CE marking. It is powder-coated and painted in the colour RAL 1023 traffic yellow for better visual perception.

The customer has transferred the risk that the requirements in their specifications are correct to the external partner, in this case Carl Stahl. The customer is therefore on the safe side that all the information in their specifications is correct.

What alternatives are there for motor handling?

For asymmetrical loads with an off-centre centre of gravity, slinging with classic load suspension equipment is too high a safety risk. So-called load tilters are suitable for keeping the load in a horizontal position during the lifting process.