Quick and easy design and visualization of load handling devices

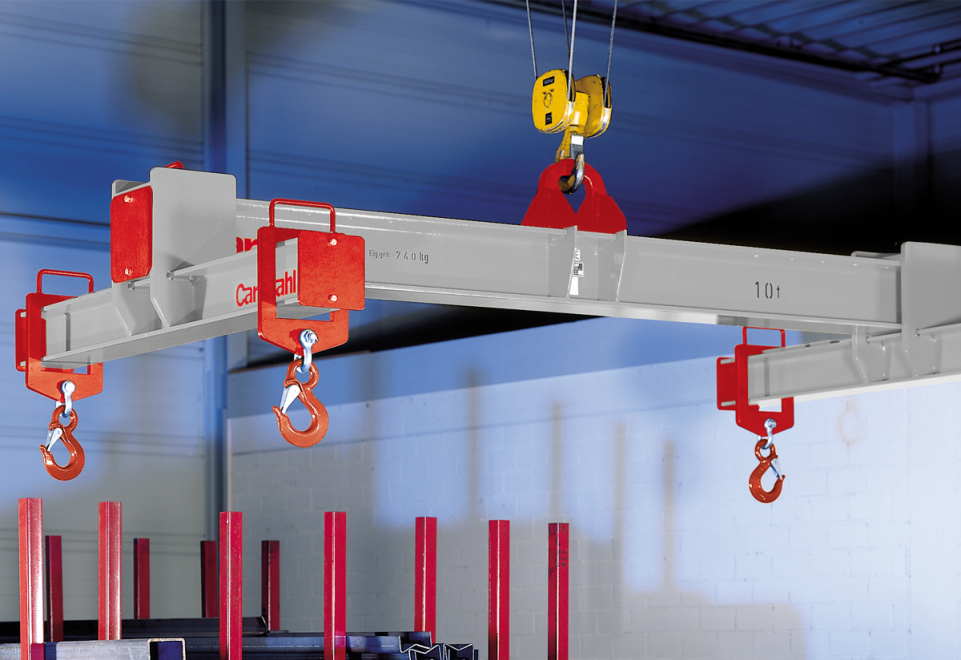

In most cases, load handling devices are not off-the-shelf product solutions, but special solutions individually adapted to their place of use at the customer. They improve the ergonomics of load handling and ensure process optimization in value creation. At the same time, they should be easy to operate but still robust. However, how and where they are manufactured has a decisive influence on their safety, reliability and service life. The manufacture of such load handling devices requires know-how and experience. Both attributes that the certified company Carl Stahl has been successfully offering its customers for decades. But how do customers get their hands on such load handling equipment? One way can be the digital lifting beam configurator developed by Carl Stahl.

The right load handling attachment in just a few steps

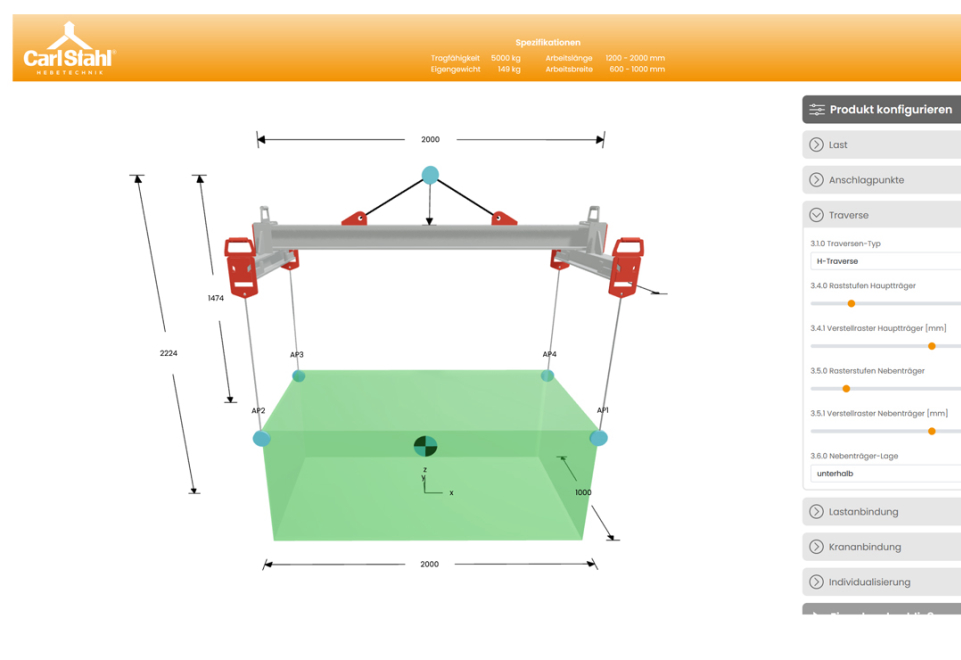

The digital lifting beam configurator developed by Carl Stahl offers customers another way to find their load handling device in addition to the "classic way" of personal expert advice. The configurator can visualize a load handling device online that is exactly tailored to the customer's needs. How does it work? The customer enters the relevant load parameters (weight, dimensions, center of gravity) and the conditions on site (crane hook size, spatial conditions) directly into the configurator. The input is intuitive, simple and carried out in just a few steps.

The configurator then calculates the static protection for the lifting beam live and designs the product according to the entered specifications in a weight- and price-optimized manner. The product is then displayed as a 3D model. The model generated online can now be transferred to the inquiry process. To do this, the user clicks on the "Send inquiry" button in the configurator after completing the required entries.

Once the product inquiry has been sent, the customer receives an e-mail with the contact person at Carl Stahl and a link that can be used to call up his configuration again at any time. Once the product inquiry has been received by Carl Stahl, an expert contacts the customer to clarify the technical details and general conditions. This ensures that the customer has not overlooked anything. In addition, special solutions and individual wishes can also be incorporated and implemented during this discussion. Only then does the customer receive his individual offer. In the case of an order, the release drawing follows before the load handling attachment goes into production.

What are the advantages of the configurator?

The configurator is generally intended for all target groups. From the customer, to the Carl Stahl consultant at the customer's site, to the project coordinator and finally to the design engineer. The primary goal in developing the truss configurator was to optimize the quotation and order workflow for standard load handling devices that are requested very frequently, but with slight variations from one another. Currently, there is no comparable configurator on the market that implements all the points described and offers the same advantages. All known configurators for trusses are database-based and recombine prefabricated components, at best displayed in a viewport. With the Carl Stahl configurator, an individual product is created live. Carl Stahl manufactures its load handling devices at 4 locations on approximately 1,250 square meters. Consistently high quality is ensured by certified processes and trained skilled workers.

Click here to go to the configurator.