If you're responsible for the transportation of heavy coils, like slit strip, you probably use a mixture of steel straps, belts, wooden wedges and so on to keep the coil secure in transit.

This presents a danger; if secured incorrectly, both the expensive material and worker are at risk.

With Carl Stahl's slit strip transportation solution, the handling of slit strip can be safe and efficient. With our transport system specifically designed to address this challenge, you can improve your workflow and protect your workers and product.

What are the risks when transporting coils like slit strip? Well, if secured incorrectly, the load could roll away and get damaged. A purpose-made transport device made especially for slit strip (and similar products) simplifies the process and removes risk.

Slit strips are vulnerable to damage - the surface and edges of the slit strips can bend and scratch very easily.

Our transportation solution ensures the slit strips are stored in such a way they can't move freely, with no exertion of pressure.

Due to their vulnerability and shape, slit strips are usually stored and transported lying down. To use them, the heavy coils need to be maneuvered and erected; taking time and energy.

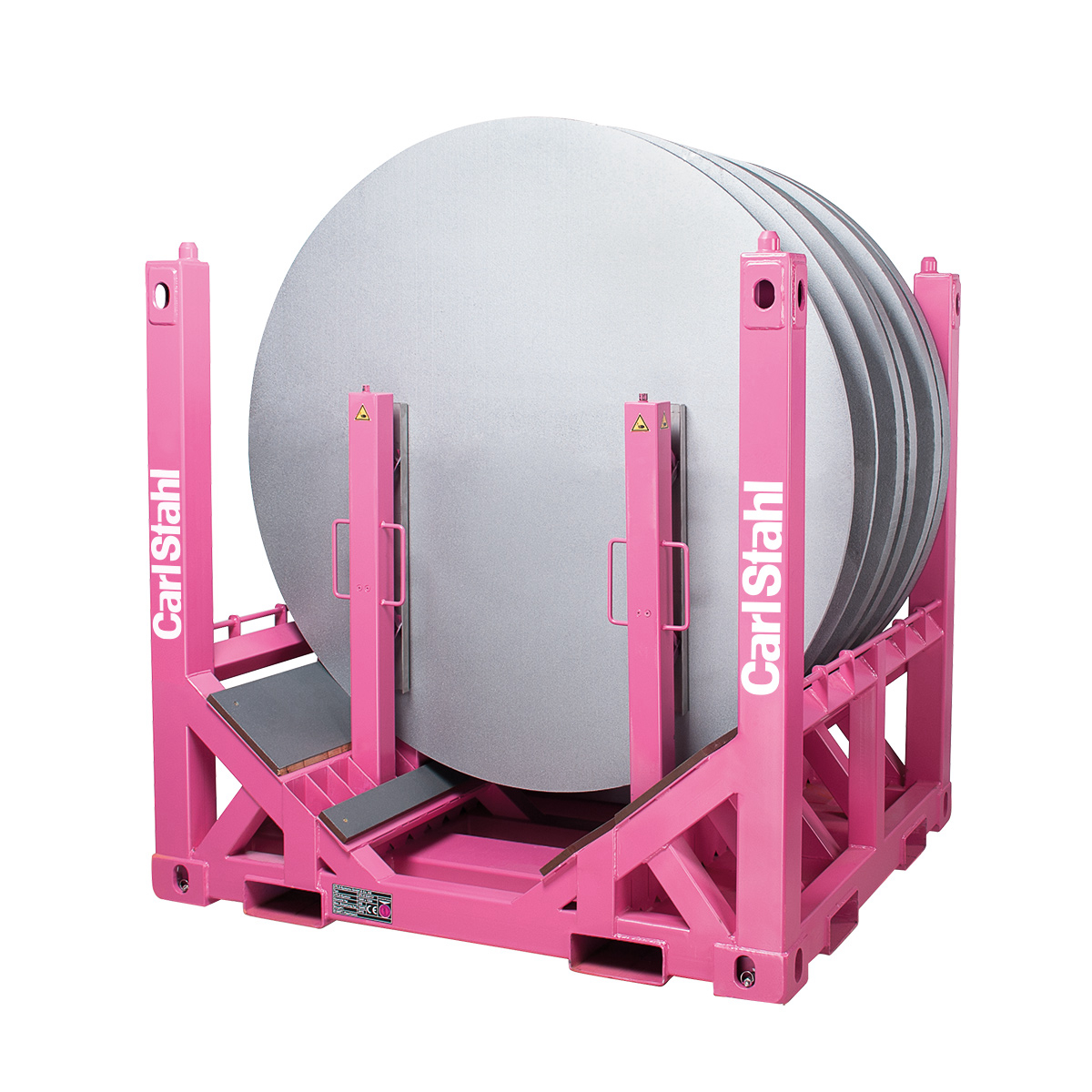

Our coil handling system transports the slit strips standing upright, saving time. The material is fed into its machine and unrolled directly.

An innovative and targeted solution, the Carl Stahl Coil Handling System supports both the intra-logistics and safe storage of slit strip.

Our CSCH streamlines the whole process - from manufacture, through shipping and final processing of the slit strip.

The CSCH coil handling system is the perfect solution for the transportation of slit strip for two main reasons: Firstly, the load is fixed inside the transportation device without any damage to the material. Additionally, the CSCH device is designed to be secured on loading areas.

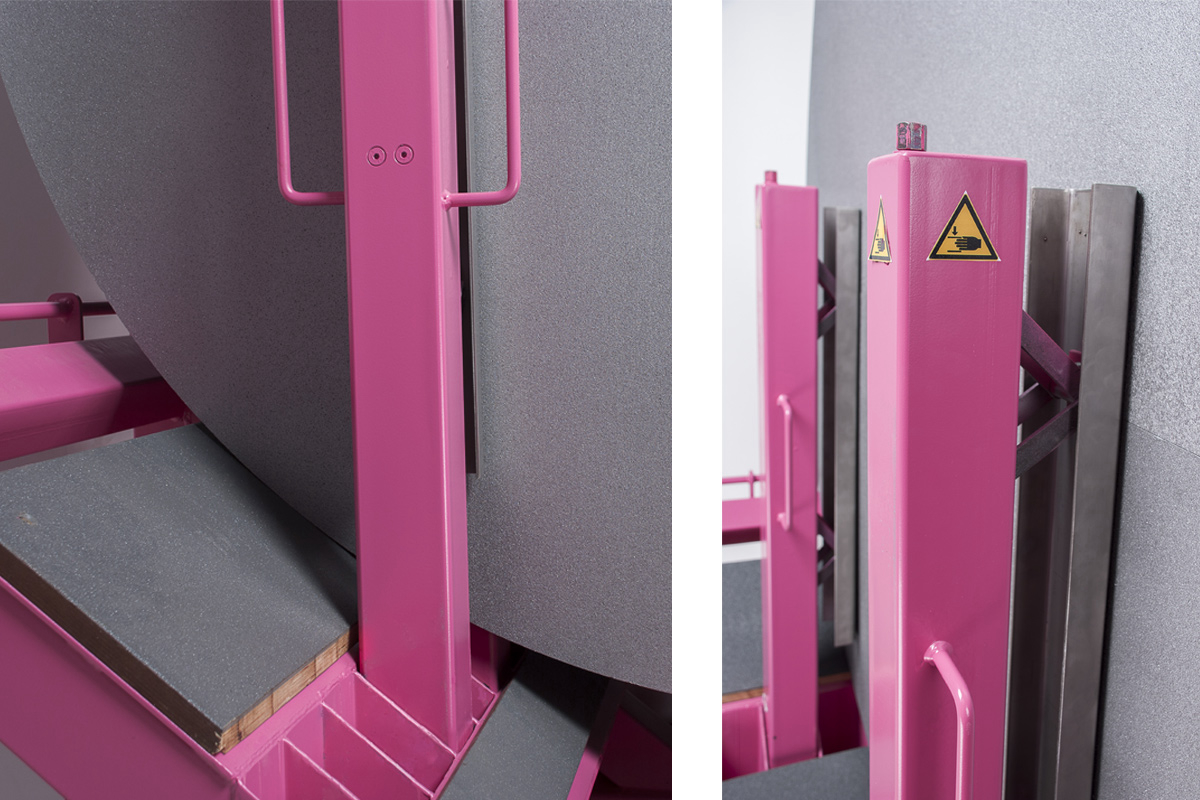

The slit strips are arranged in the CSCH in such a way they are perfectly well-protected from damage. Any components that come into direct contact with the material are protected by plastic. The stanchions that secure the slit strips can be exchanged to suit the respective coil.

To maximise efficiency, slit strips are transported and stored upright in the CSCH device, allowing the worker to process the slit strip directly from the device.

For transportation, the operator can either attach a chassis with wheels beneath the CSCH, or it can be moved by crane or forklift. Our CSCH system is available in a stackable format, which further simplifies storage and transport.

The CSCH frames are available in various configurations to accommodate different sizes and weights. Additionally, the stanchions can be exchanged and the whole device is compatible with other lifting devices.

The CSCH is approved by TÜV Süd and certified by the DGUV. In addition, the system complies with the DIN ISO 1161 standard.

Slit strip needs to be upright when it's processed. Previous transport solutions take place lying down which means the coils need to be maneuvered into position before use; time consuming and risky. The CSCH holds the slit strip coil in an upright position, both during storage and transport, so it's ready to use.

The CSCH is suitable for every step in the logistics chain. The manufacturer can store the slit strip in the CSCH immediately after production and hand it over to the carrier. It's then transported to be processed and then stored in the CSCH. In principle, slit strips never have to leave the CSHS system.