According to Ai assistant ChatGPT, a specification sheet in construction is 'a detailed document that provides comprehensive information about materials, equipment, systems, and construction methods required for a project'.

It serves as a guide for contractors, engineers, architects, and other stakeholders to ensure the project is executed according to the design and quality standards.

The specification sheet acts as a blueprint for the technical and material aspects of a construction project, complementing the architectural and engineering plans.

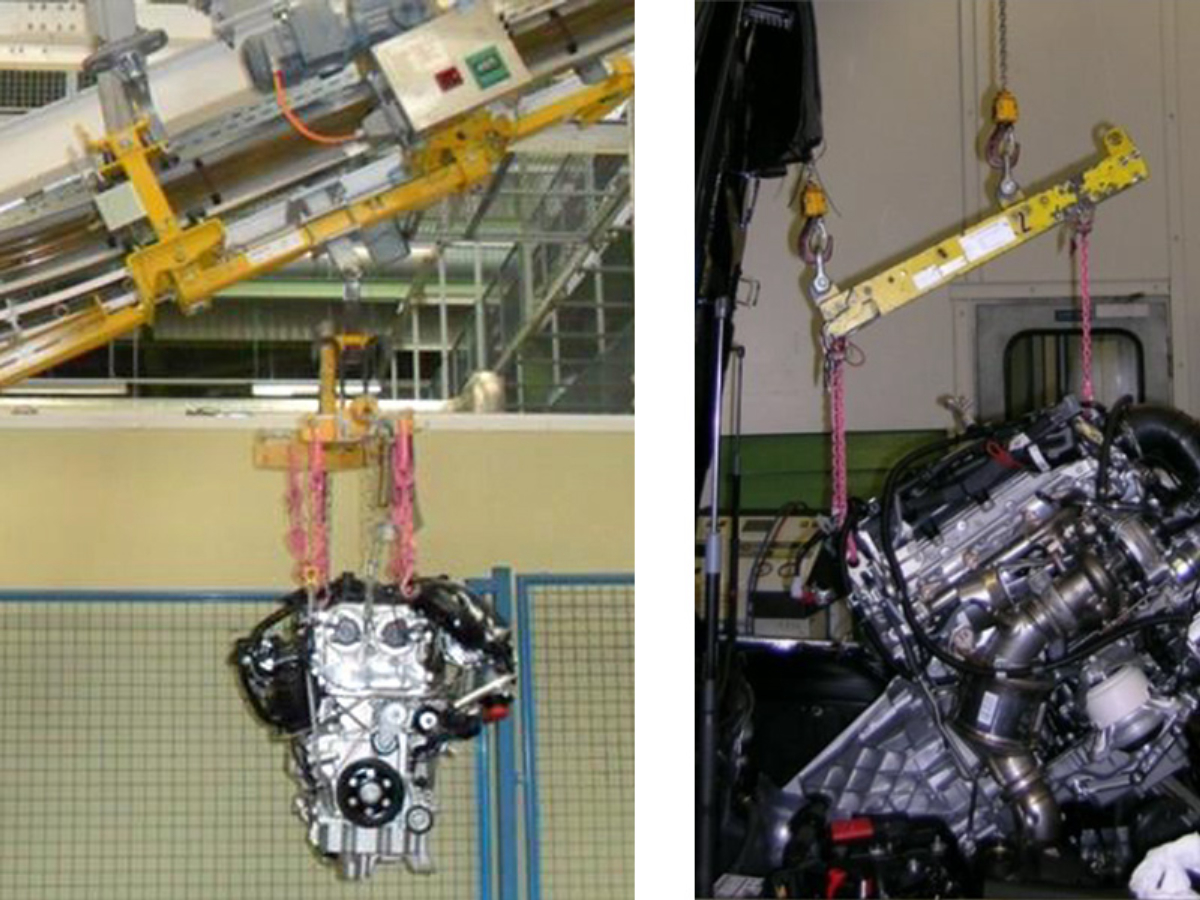

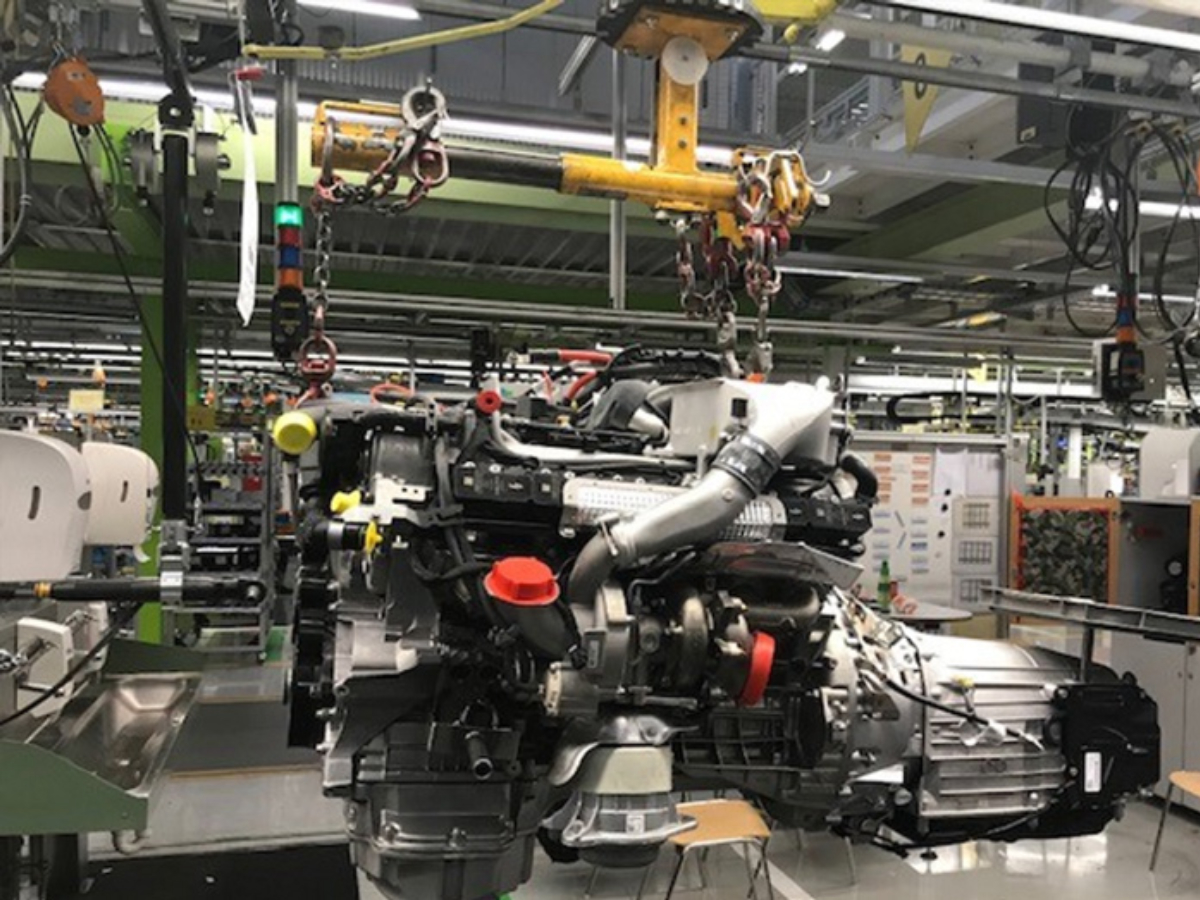

No two engine models are the same. Each engine has its own dimensions, centre of gravity, shape and weight. As an engine is lifted and transported, it needs to be perfectly level and safe.

Standard load handling equipment isn't versatile enough to address the various differences in each engine. With that in mind, a customised solution is required.

Mercedes AMG GmbH faced this challenge when looking for a solution for handling the M279 engine. Unsure how to specify and design a bespoke solution, Mercedes consulted a Carl Stahl expert.

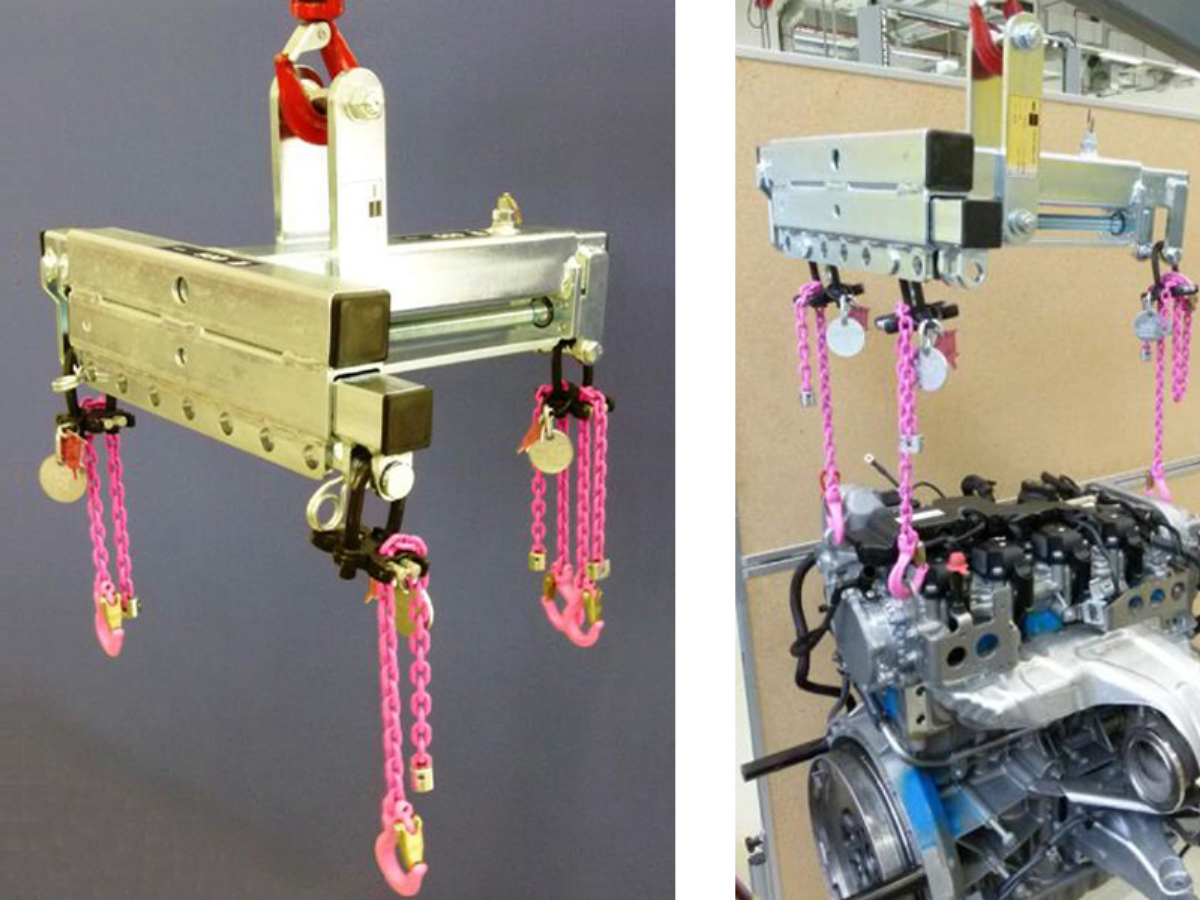

The standard solution for engine handling consists of an 'upper suspension eyelet' mounted on the engine. Additionally, there's a further suspension eyelet on the control cover. This allows the engine to be securely attached at several points with the help of a load cross member and attachment chains.

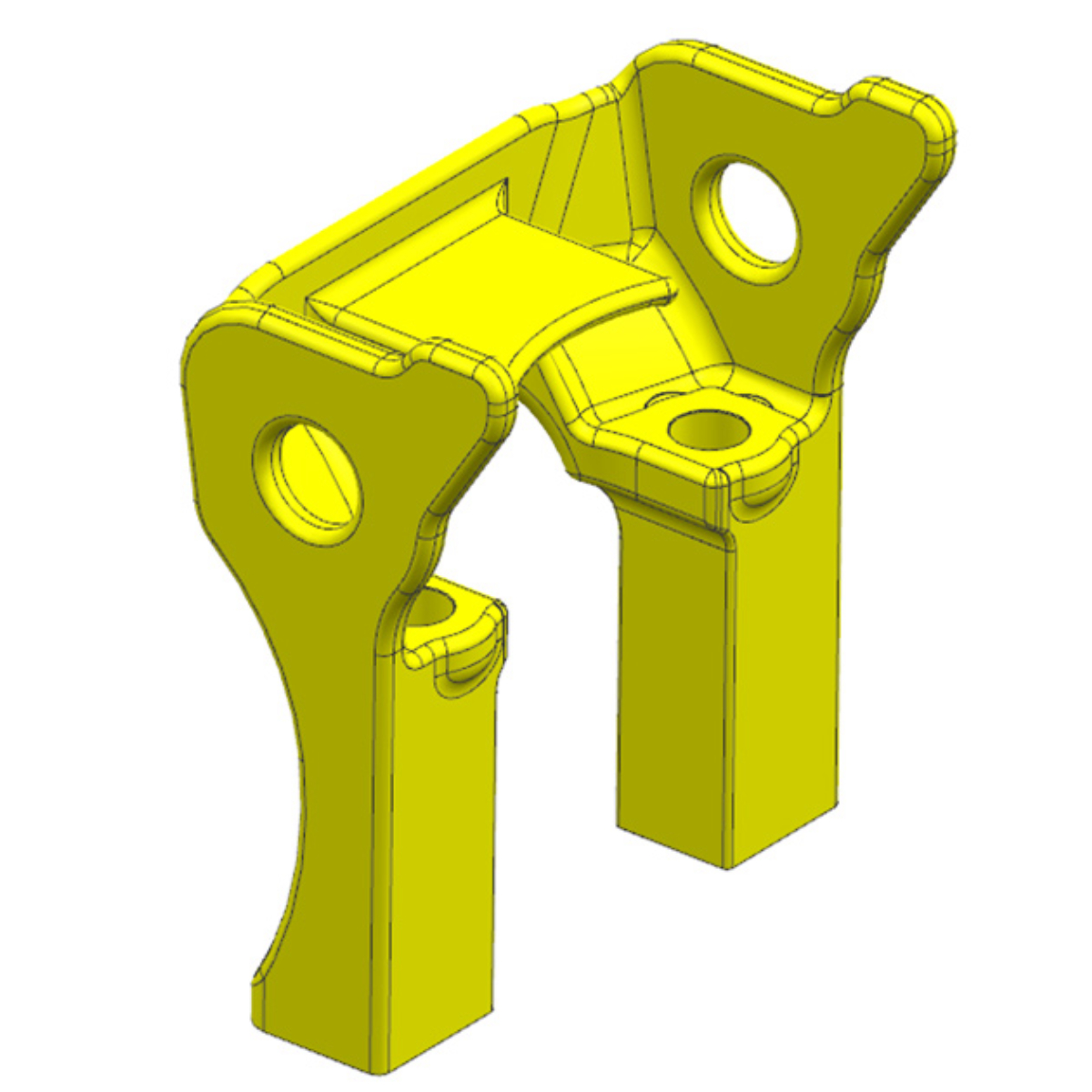

As mentioned, Mercedes consulted a Carl Stahl expert for advice. It was determined the suspension eye should either be a load suspension device or an attachment point.

Subsequently, Carl Stahl was commissioned by Mercedes-AMG GmbG to oversee the creation of a specification sheet.

To achieve this, the Carl Stahl expert specified the requirements of the machine directive are, with a focus on the design requirements for the load handling attachment. Next, requirements for the manufacturer, and then requirements for legally compliant documentation. Additionally Carl Stahl developed a prototype proposal. Collectively, this information formed the basis for a specification sheet which later became evidence for tender.

The resulting suspension eye is powder coated, painted in the colour RAL 1023 traffic yellow and is permanently labelled with its internal ref. number and CE marking.

A third party specialist takes legal responsibility for the accuracy and compliance of the content of the specification, providing the client with reassurance.

For assymmetrical loads with an off-centre centre of gravity, our tilt stand is suitable for keeping the load level during the lifting process.