What is a lifting point?

According to the Lifting Operations and Lifting Equipment Regulations (LOLER) 1998, lifting points are either detachable or fixed devices that are attached to a load so it can be lifted.

Collectively known as 'load suspension equipment', lifting points, slings, magnets and cablegrips are available in our Webshop.

Are lifting points compulsory?

According to machinery directive 'Supply of Machinery' regulations 2008 (UK), if a load or its various components can't be moved by hand due to its weight, size or shape, it must be equipped with fastening devices, or be shaped in such a way that load-bearing devices can be applied.

What are the mounting types for lifting points?

The most common types of lifting points are 'screw on', 'welded' or 'plug in'.

Consider the following instructions when installing lifting points:

- The load must not damage the slings

- The sling must not damage the load

- Lifting points should be located so the forces applied can be absorbed by the base material of the load without deformation

- Lifting points must always sit firmly and flat on the screw mounting surface

- Select a suitable thread-length

- The screw-in depth depends on the grade of the screw and the base material of the load

- If the tread-length is too long or short, there's a risk of thread breakage; possibly causing the load to tip or slip out

- Use an online calculator to calculate the ideal thread length

- Screws can be measured in cm or inches

- Weldable lifting points should be installed by a certified welder in accordance with EN 287-1

- Always follow the installation instructions from the lifting point manufacturer

- Manufacturer approval (of the load) should be available

What are the requirements of lifting points?

Marking and load capacity

A lifting point must be clearly marked with its manufacturer, type, CE mark and load capacity. Keep in mind, lifting points can have a preferred load direction, which may result in a different load capacity from the mark on the lifting point. Lifting points must not be loaded beyond the load capacity.

Avoid the use of self-made lifting points.

Inspecting the Lifting points

As a load suspension device, a lifting point should be inspected in accordance with DGUV Rule 109-017 and BetrSichV regulations.

Who is responsible for lifting loads?

There are two parties involved in a heavy lifting operation; a crane operator and a slinger signaller. The slinger signaller is the person who attaches and detaches a load from lifting equipment and is responsible for ensuring that loads are lifted and placed safely.

How heavy may the load be?

If a load (a machine part, for example) is to be handled with lifting equipment, its weight must be indicated legibly, permanently and unambiguously, usually on its type plate.

The weight of a load is calculated from the density of a material. The depth, width and height of the load is multiplied by its density. For example, (1000mm x 1000mm x 1000mm) x 7.9g = 7900 kg/m³

What is the symmetrical property of the load?

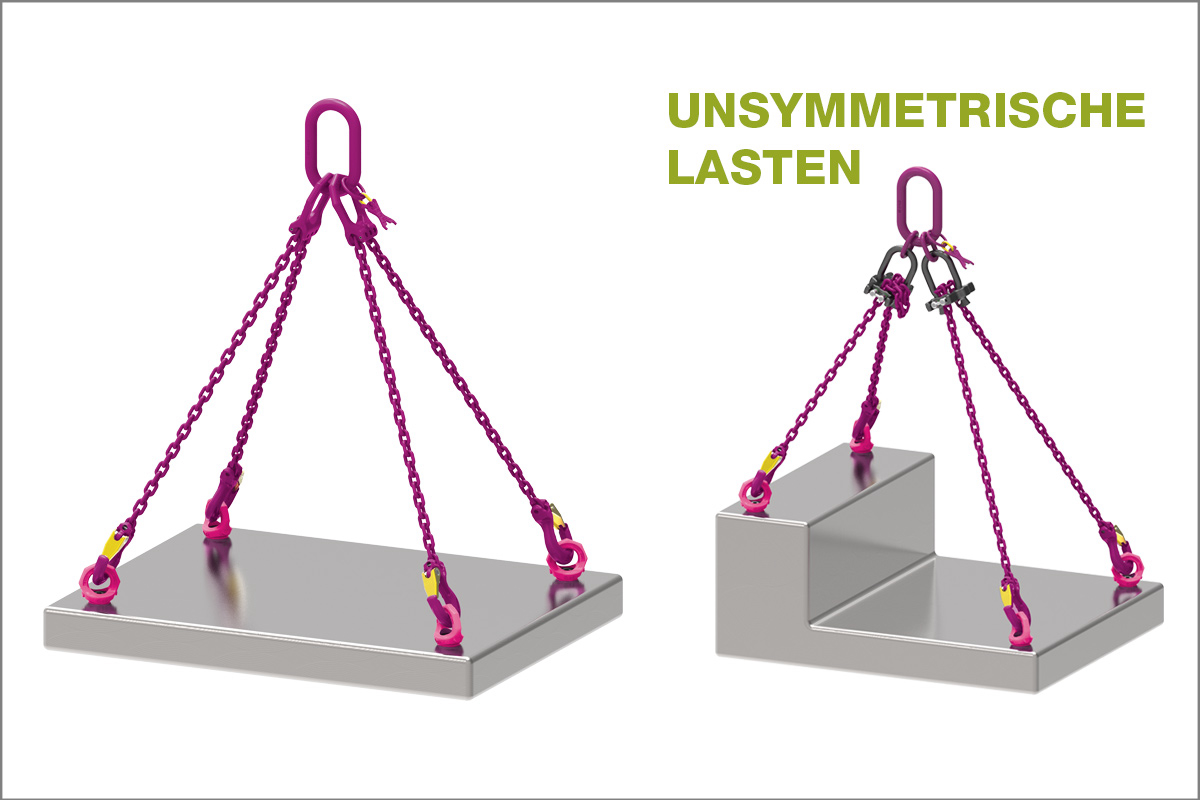

In geometry, an object is considered to be symmetric if you can draw a line in its center, called the axis of symmetry, and the sides of the object on either side of the line are mirror images of each other.

Loads are often not symmetrical, with an off-centre mass distribution (as illustrated in the photo on the left). It's important to determine the centre of mass. The load's centre of gravity should be directly below the central lifting point.

To prevent a non-symmetrical load from tipping, you can use a multi-strand or shortenable sling, a weight balancer or a variably adjustable load handling device.

What kind of handling is planned?

When planning a heavy lift operation, consider what handling should be done with the load. Does the load need to be turned or tilted? There are suitable lifting points for any eventuality, including rotating and foldable designs.

Contact us for expert advice about lifting points.

Are jerk-free movements required when lifting?

In some circumstances, a lifting point might cling, releasing accumulated tensions abruptly. This transverse load can lead to unpredictable movements and vibrations and in the worst case scenario cause structural overloading of the components.

We recommend ball bearing lifting points to prevent unintentional issues. There are double ball bearing variants for large loads.

How long is the lifting point connected to the load?

Screwable or pluggable lifting points can be assembled and disassembled when required, although some applications require permanently attached lifting points.

When assembling your lifting point, we recommend using the original, inspected screws, washers and locking nuts provided by the manufacturer.

The less versatile eyebolts and ring nuts should only be used for permanent attachment to components like motors, control cabinets, gearboxes for transport purposes.

Weldable lifting points are intended for permanent, inseparable connections.

Which connection should the lifting point have?

Lifting points have various connections; loops, hangars, rings, eyelets or shackles. The type of sling required will depend on the size and style of the connection.

Do lifting points need to be checked?

Lifting points should be inspected by the slinger before use, after use and at least once a year by an expert.

During the inspection, check for a correct screw (if applicable), severe corrosion, cracking of the weld, fractures and deformations. Check that all parts and components are present, safety devices are functional and look for any signs of unacceptable heat damage and excessive wear.

Check for cross-sectional changes of over 10% and heavy wear on the bearing (located on the suspension link and base body).

In principal, if there are doubts about the safe condition of the lifting point, withdraw it from use and report it to the line manager.

Storage

To prolong its lifespan, a lifting point should be stored properly; upright and protected from adverse weather conditions and aggressive substances.

Contact us to discuss your requirements.