Ordinarily, grippers are available in a wide range of specifications, each designed to handle a specific load, shape or application. Workplaces with several different loads to handle require several grippers; with the associated high costs. This can be time-consuming, requiring extensive research with such a huge variety of grippers available on the market.

To safe time, storage space, cost and complication, a universal gripper that can adjust to a range of shapes, sizes and weights can provide the perfect solution.

Coated surfaces such as paint or powder are sensitive and require special care when being handled. Industrial grippers risk damage to the vulnerable surface. Surface damage can impair appearance and function of the load and must be avoided.

Common solutions include protective coatings on the inner surface of a gripper or protective covers for the load. However, these solutions require an additional step in the workflow and take more time.

Form-fit grippers are recommended where a load has an oily or slippery coating.

Solutions for handling fragile loads are even more complex. Thin-walled loads (such as fabrics and paper) or objects made of glass or porcelain are very sensitive to pressure, so force-it grippers are not recommended. A gentle and evenly distributed pressure can only be achieved with a positive fit and large contact surface.

Efficient warehouse organisation is crucial to allow convenient access to and handling of loads. However, storage space is often very limited and can result in challenges with cumbersome and unsafe handling processes.

Special racking systems for confined spaces, or automated storage systems can work, but can also incur comparatively high costs.

A versatile gripper with a structurally narrow gripping area can be a great addition to a tight storage situation to maximise storage space.

If the challenges discussed above sound familiar, you're probably looking for a gentle, versatile gripper that can handle complex requirements.

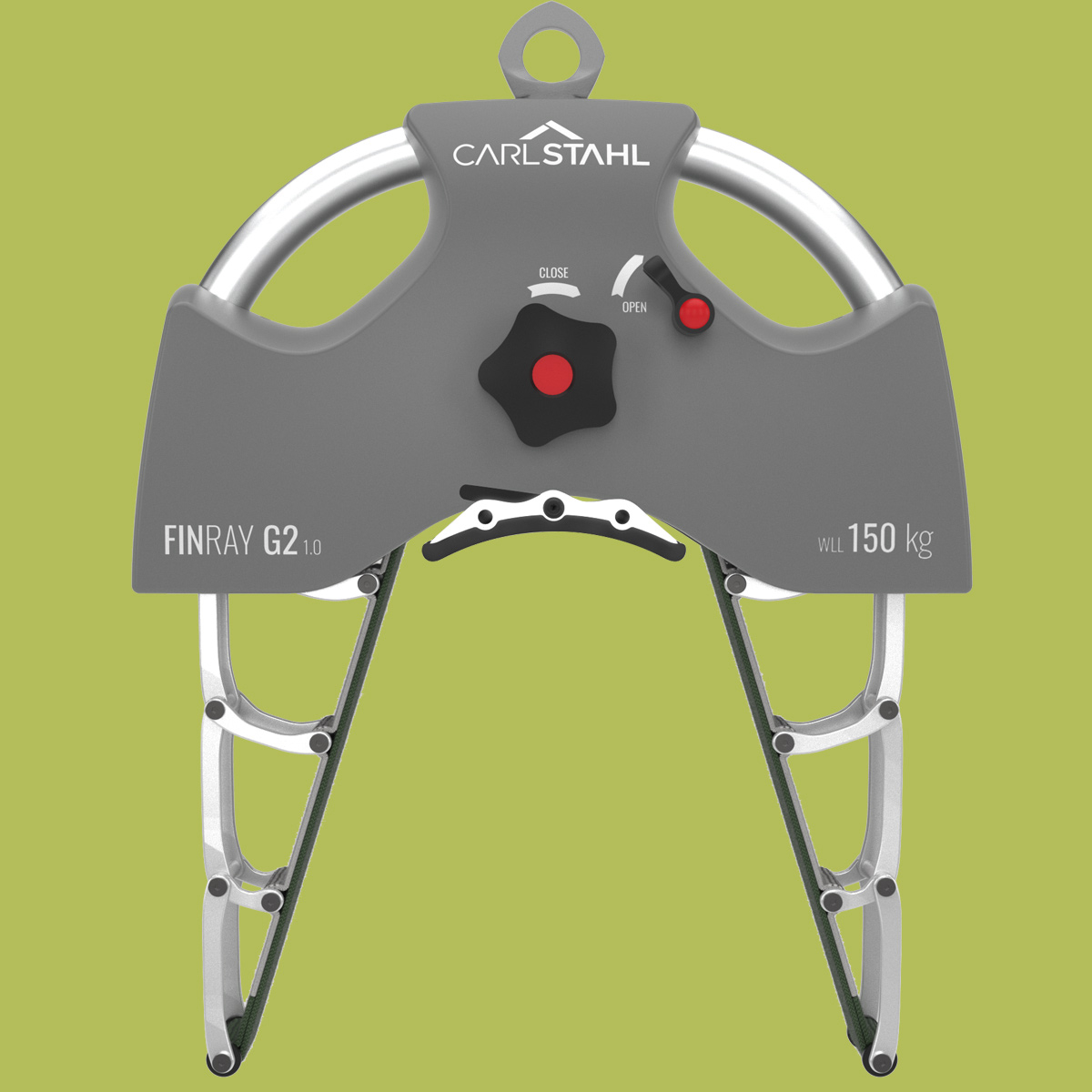

The innovative FinRay gripper from Carl Stahl, with its bionic influences expands and contracts dynamically to accommodate all shapes, sizes and weight of loads. It exceeds the performance limits of commercially available grippers while maintaining true flexibility.

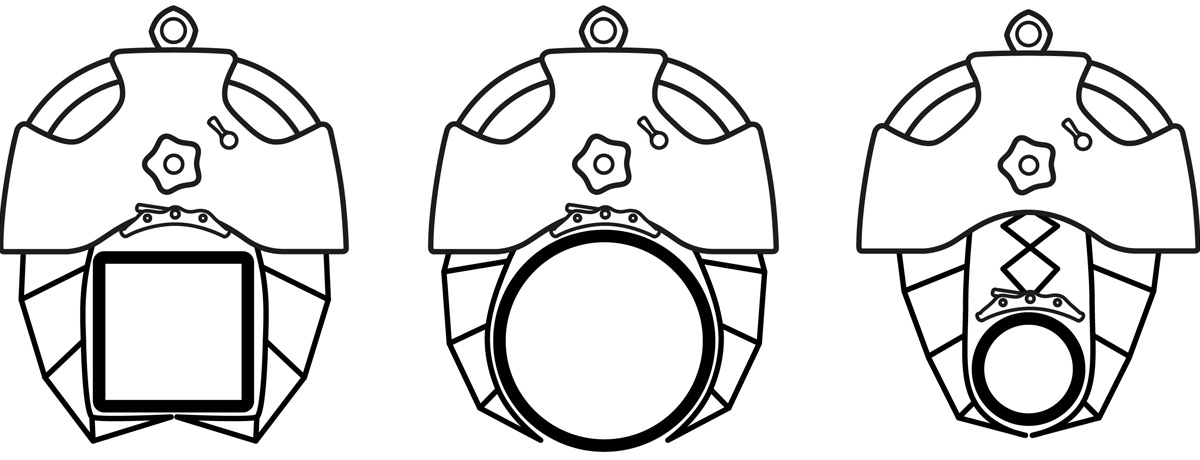

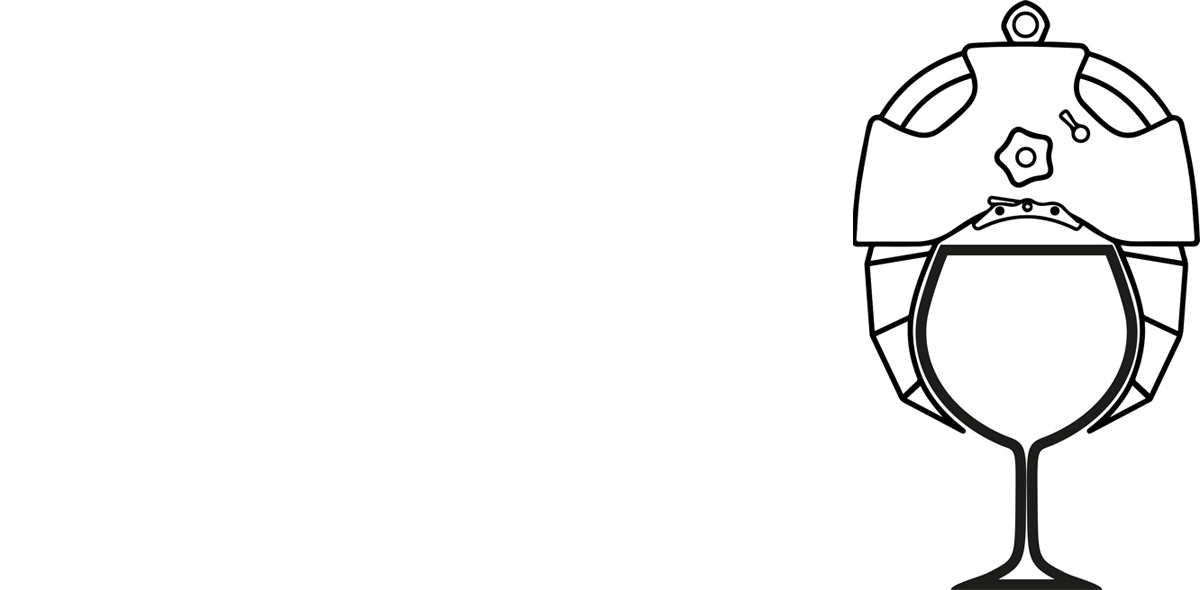

With its bionics-inspired self-adaptability, the FinRay gripper will adapt effortlessly to securely grip almost any round or angular shape.

The FinRay gripper avoids damage to its load, however delicate thanks to even and low contact pressure.

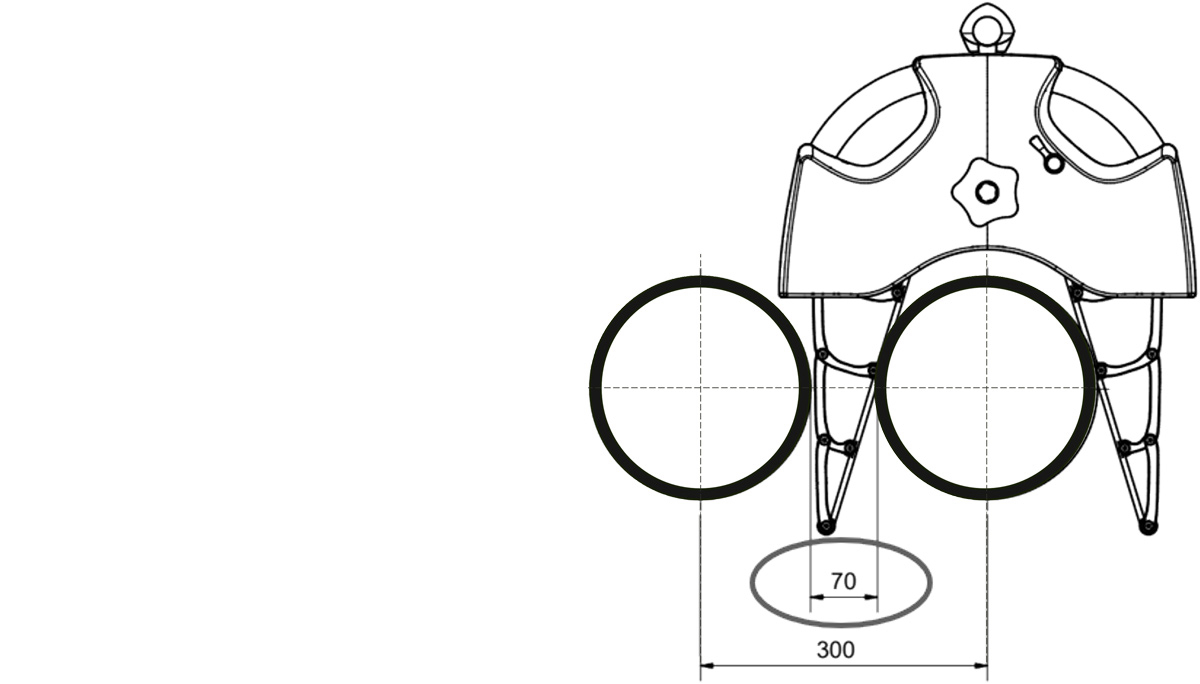

For effective space-saving, the FinRay G2 gripper has a comparatively narrow gripping space.

The Mhe FinRay G2 gripper from Carl Stahl is the innovative, versatile solution to conventional, inflexible grippers. It offers unparalleled flexibility for adaptable and gentle gripping of loads or all shapes and sizes. Its bio-mechanical fin ray effect ensures a high degree of adaptability when gripping loads of different shapes and diameters.

The form-fit connection between the load and the gripper, in which only the soft, internal, fabric strip has contact with the load ensures a gentle but secure grip.

In nature, a fish fin will curve around a pressure point. Carl Stahl used this 'fin ray principle' in the development of the FinRay G2 gripper to boost versatility and create a gentle grip.

The FinRay G2 universal gripper is operated manually. A star grip enables the gripper jaws to be closed, while a lever releases the fixation and opens the gripper. A hold-down device (included with the FinRay G2 gripper) ensures a three-point pick-up for loads that are prone to tipping and increases the gripping range for small load geometries.

The FinRay universal gripper is designed to address a wide range of applications and is suitable for loads of various sizes, weights and shapes. It's particularly recommended when handling different load geometries and where materials require a gentle grip.

The FinRay's versatility and adatability set it aside from conventional grippers.

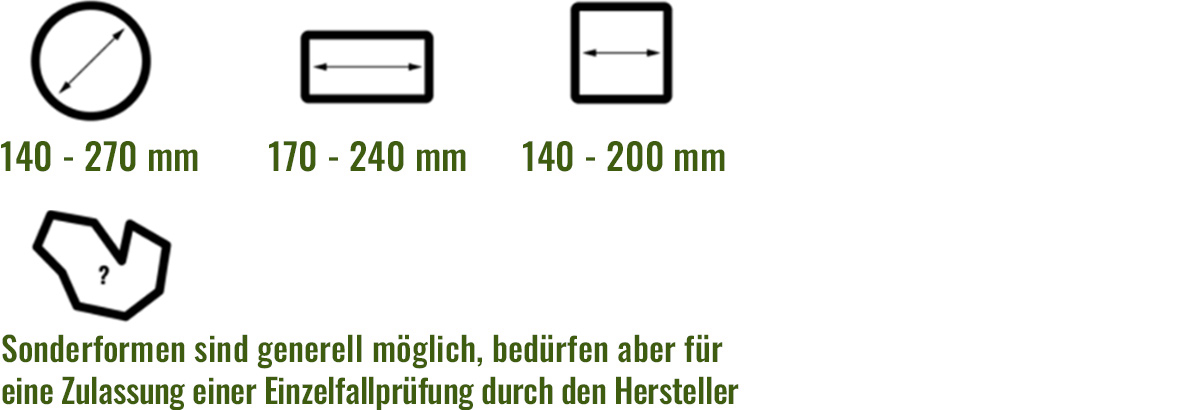

The FinRay gripper is flexible, however the graphic below provides a rough guide to the gripper's limits. For unique, non-geometric loads, get in touch with a Carl Stahl expert.

A hold-down device is supplied with the FinRay gripper, to ensure loads are stabilised when attached to the FinRay's grips.

This is essential where small loads or long loads of more than 80cm.

In exceptional cases, for instance with a load with a short load length but sufficiently large load diameter, or where using several FinRay grippers simultaneously, the hold-down device can be excused.

Loads between 20-150kg can be handled safely with the FinRay gripper.

Loads under 20kg need to be tested by the manufacturer prior to being handled.