The Provision and Use of Work Equipment Regulations 1998 (PUWER) are a set of laws in the UK that aim to protect workers from harm by ensuring that any equipment they use at work is safe and suitable for the intended purpose. This includes ensuring equipment is properly maintained, inspected, and that workers are adequately trained on how to use it safely.

Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) focuses specifically on lifting equipment. LOLER defines lifting equipment as any equipment used for lifting, lowering or suspending loads. LOLER requires that all lifting equipment undergoes thorough examinations at specified intervals by a competent person.

A competent person is someone with:

The Health and Safety Executive (HSE) provides guidance on what constitutes a competent person https://www.hse.gov.uk/work-equipment-machinery/thorough-examinations-lifting-equipment.htm.

PUWER doesn't specify a generic inspection frequency for all equipment. However, it requires employers to conduct risk assessments to determine the type and scope of inspections needed for their specific equipment.

This risk assessment should consider:

Based on the risk assessment, employers should establish a program for:

LOLER has specific requirements for lifting equipment. All lifting equipment must undergo a thorough examination by a competent person at least every 12 months.

The HSE website provides further information on equipment inspection.

Carl Stahl has decades of knowledge in the field of testing and repair.

We have hundreds of experienced Test Engineers on the road across the globe to inspect, test and service equipment.

Here in the UK, we have a dedicated test centre based in Rotherham, South Yorkshire, where our team of engineers run comprehensive inspections and issue the related legally compliant certificates and documents.

Our engineers keep up with innovations in technology and up-to-date regulations and are required to maintain relevant qualifications and awards.

When you choose Carl Stahl you get:

At Carl Stahl, our testing services begin long before the actual tests are conducted. We provide expert guidance throughout the entire lifecycle of your equipment, from initial design and selection to ongoing maintenance and inspections.

We don't just sell products; we offer comprehensive solutions. Rely on us for complete peace of mind, we'll ensure your equipment meets all regulatory requirements and is ready to use.

Our team of qualified engineers ensures the highest level of safety and reliability.

Chat to our engineers about our inspection service - don't worry, there's no obligation.

Item labelling

Equipment due for inspection must be marked clearly and concisely. Type-plates, QR or barcodes or RFID technology are commonly used. Take a look at the Chipster from Carl Stahl - our innovative RFID enabled micro-cable tie that can be conveniently attached to inventory items.

Carl Stahl branded products are already marked by default and automatically added to your inventory in the Equipment Portal when purchased.

Identification

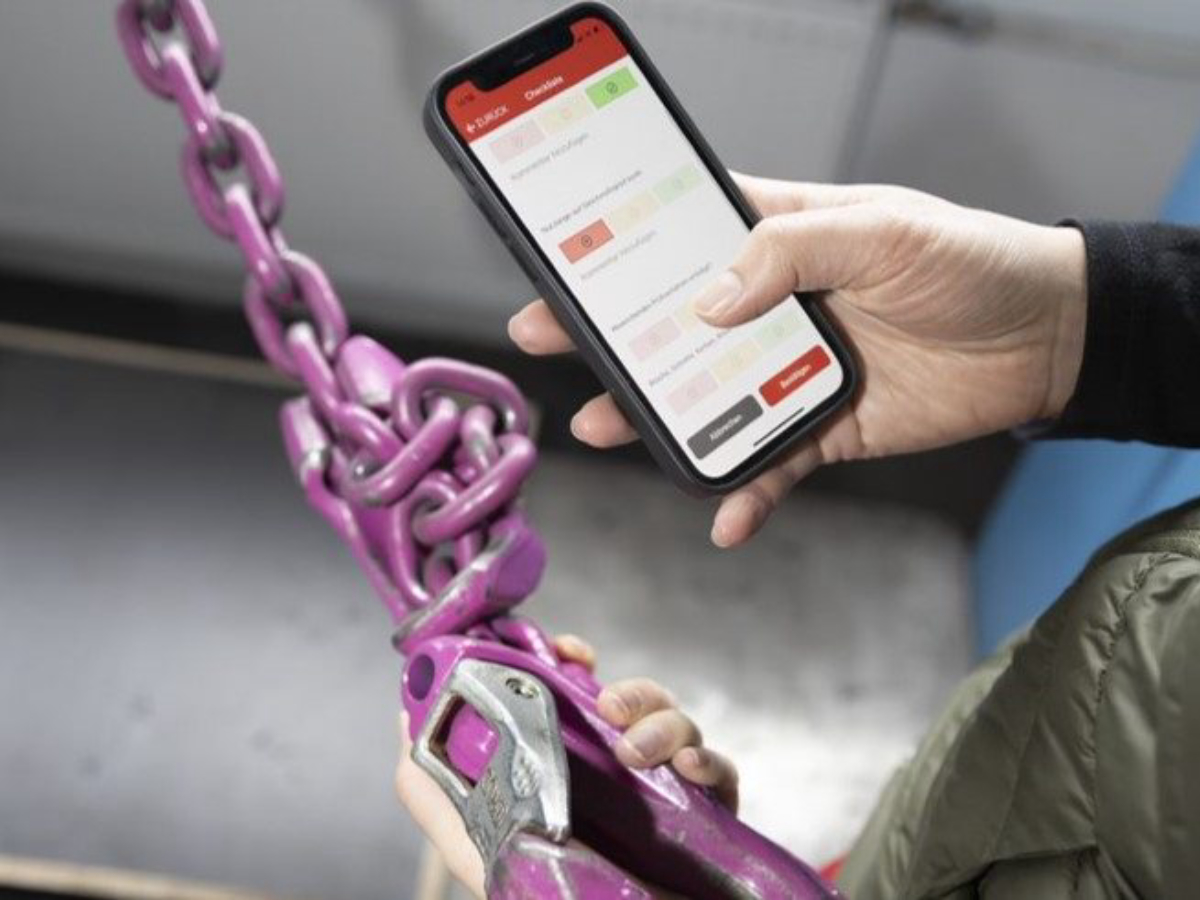

The Carl Stahl engineer will scan the item's label or RFID tag, locating it in the Equipment Portal.

Once identified, the Carl Stahl engineer is presented with the item's service history, service checklist and supporting legal documentation, along with images and details about any previous damage or repairs.

A robust checklist

Our checklist-based inspection is tailored to meet manufacturer specifications, legal regulations and customer-specific requirements. Customer-specific requirements will include the results of the item's risk assessment.

Point by point, our engineer evaluates an item's condition before making a recommendation. The checklists, which are always up to date ensure a consistent inspection quality that meets legal guidelines.

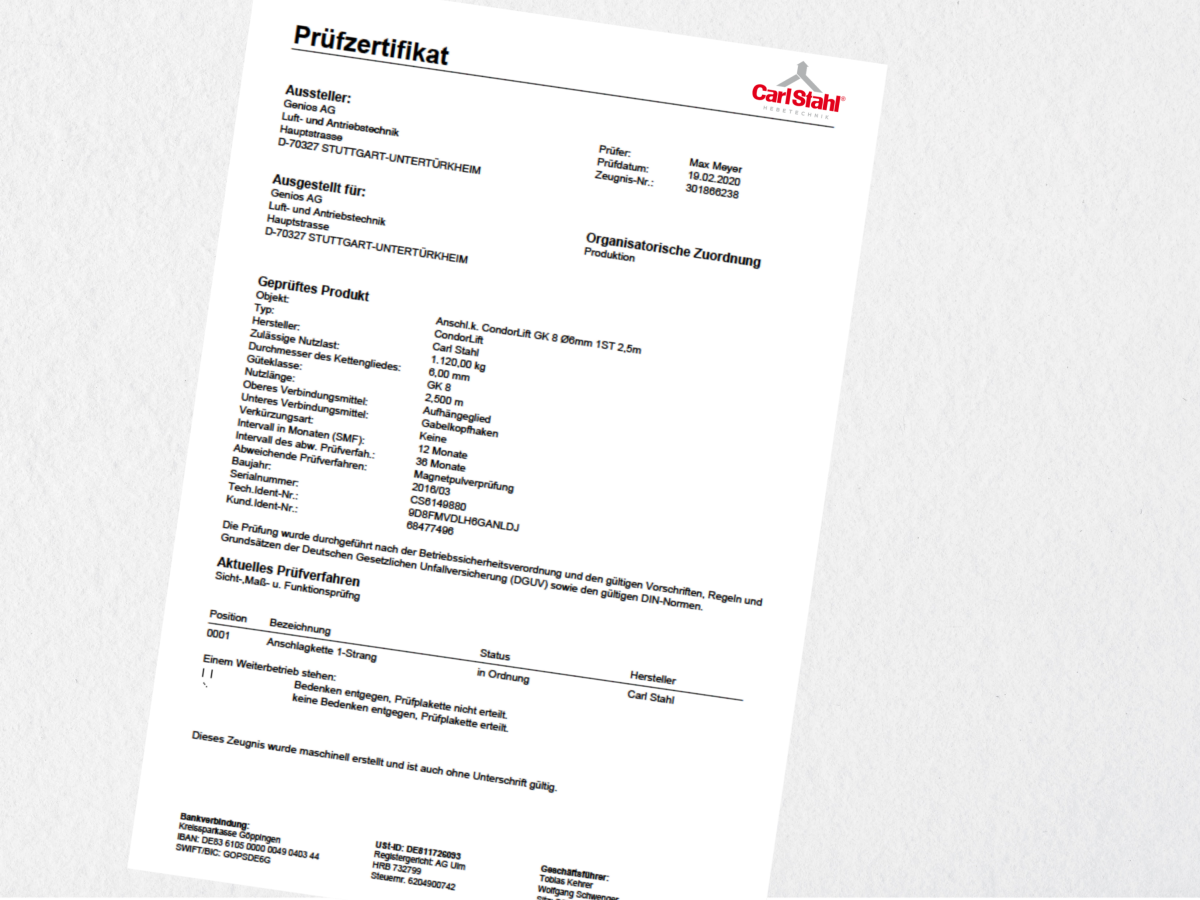

Legally compliant documentation

When an item is deemed fit for another year's use, you will receive an electronic certificate; attached to the item's record in Equipment Portal. The certificate can be downloaded in PDF format on demand.

The certificate contains detailed information including defects and damage patterns.

Comprehensive & impartial: Our expert service technicians inspect and test equipment from all manufacturers

Efficient & cost-effective: Here at Carl Stahl, we adhere to strict manufacturer guidelines and use checklists for thorough testing. Our rapid turnaround times ensure minimal downtime

Legally compliant: Our inspection service integrates seamlessly with the Carl Stahl equipment portal, providing clear, digitally documented records of all inspection results for full legal compliance

Extensive coverage: With hundreds of engineers worldwide, we offer convenient and efficient on-site or in-house testing services

Full-service support: If our inspection reveals any defects that impede equipment operation, we provide prompt and reliable repair services

Streamlined solutions: If your equipment is deemed unusable, we offer a convenient reordering option directly through the Carl Stahl equipment portal or our web shop. We can also handle the disposal process for you

Here's a selection of equipment our engineers frequently assess and inspect. This list isn't exhaustive - if your equipment doesn't appear below, don't worry, get in touch for a no-obligation chat.

Lashing chains of grades 8, 10 and 12

Aluminium jacks, pumps, cylinders, hydraulic tools

Wire rope slings, webbing slings, roundslings, chain slings, fibre rope slings, lifting points, shackles, load hooks, accessories

Travelling cranes, overhead conveyor systems, gantry cranes, workshop cranes, wall-mounted jib cranes, pillar-mounted slewing cranes

Chain blocks, lever hoists, steel winches, trolleys, return pulleys, wire rope piston, wall cable winches, multi-purpose hoists, electric chain hoists, pneumatic chain hoists, drum winches

Lifting beams, lifting forks, tongs and grabs, lifting clamp, c-hook, suction lifters with pump

Hand lifting magnet, permanent lifting magnets, electro lifting magnets

Inspections at intervals of no more than four years on stationary equipment and intervals of 12 months on mobile equipment and systems

Hand-operated and power-operated scissor lift tables, spindle lifts, automotive lifts, working and assembly platforms

Sliding gates, roller shutters, hall doors, automatically controlled windows

Multi-purpose trains, accessories

Shelf racks, pallet racks, cantilever racks, drive-in racks, drive-through racks, multi-storey racks, flow racks, mezzanines

Safety harnesses, tethers, safety ropes, energy absorbers, lanyards, fall arresters, rescue systems, descenders

Step ladders, rung ladders, fiberglass ladders, fire brigade ladders, mobile scaffolds, floor stairs, fixed ladders, two-spar ladders

Drive-over ramps, loading ramps, hydraulic ramps, drive-on ramps, stage ramps

Risk assessment, duplicates of crane books, calculations of remaining service life, load changes of trusses