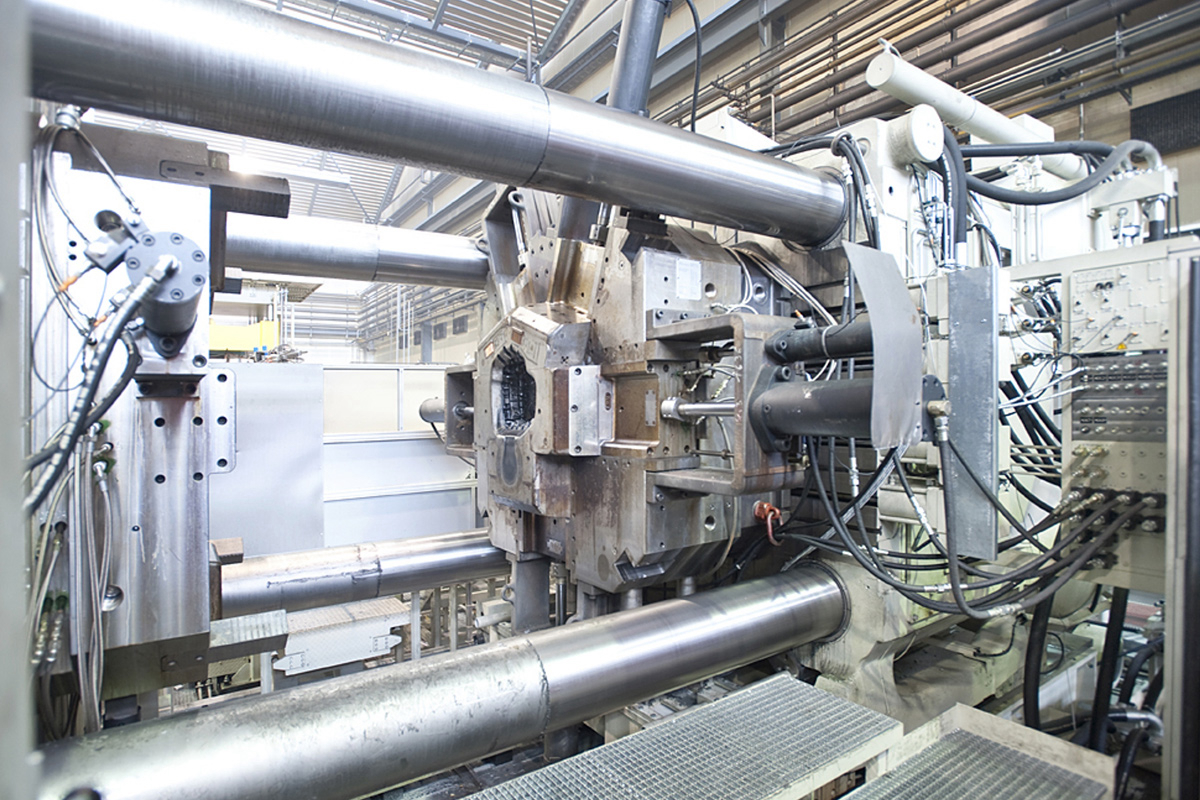

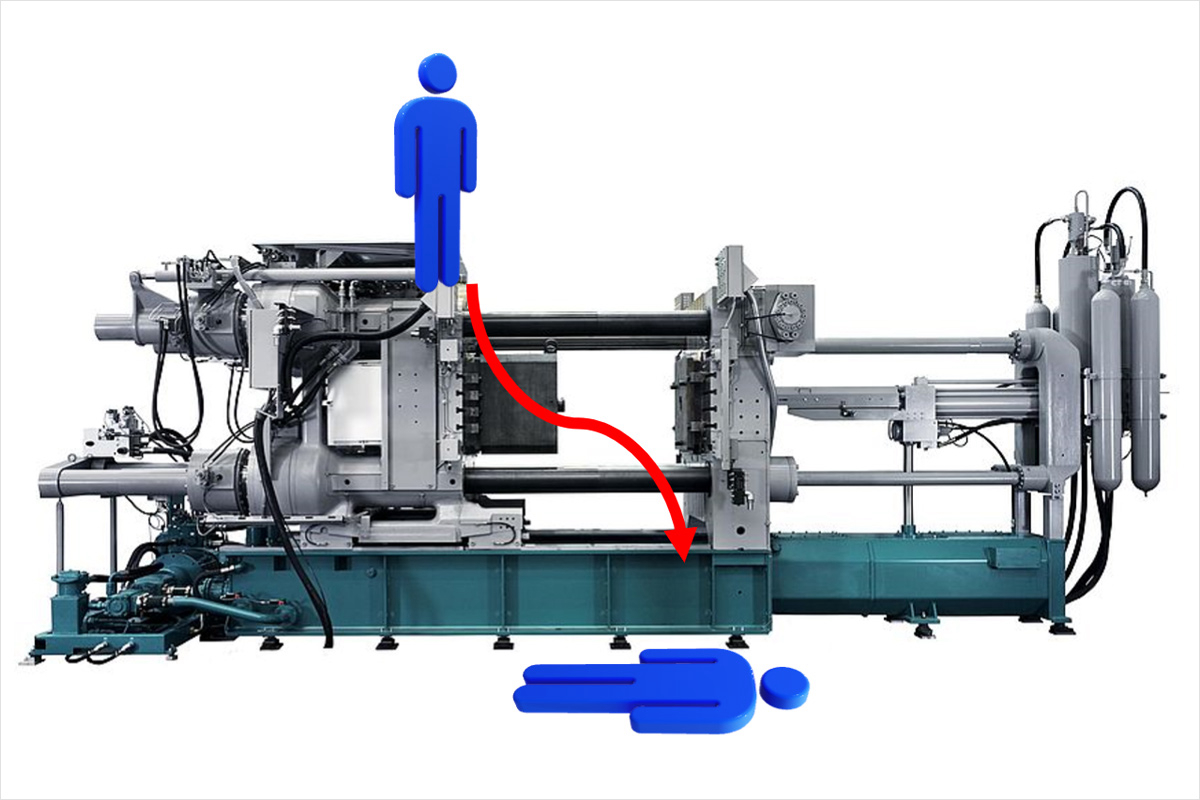

A die-casting machine, also known as a die-casting machine, is a technical device that uses the die-casting process to manufacture products or their preliminary stages. Die casting machines usually consist of a mould closing unit that is used to open and close the die casting mould. Like machine tools, die-casting machines can also have considerable dimensions. Due to the size and nature of the machine, there is always the possibility of workers injuring themselves on the machine or falling from it. Most falls occur from a height of 2 to 3 metres.

What many people don't know: The area at risk of falling starts at a height of just 1 metre. This means that if a person falls from this height, this can result in serious and often long-lasting injuries. For this reason, the employers' liability insurance associations stipulate that workers from a height of 1 m must protect themselves against the possibility of falling with personal protective equipment, but even better with collective protection. In addition, it should be the concern of every company to protect its employees in the best possible way. The tools on die casting machines must be changed regularly. To do this, it is necessary for an employee to climb onto the tools and machine and thus enter an area where there is a risk of falling. As a rule, there are no fall protection solutions on older machines. In the context of a risk assessment, this leads to a deficiency, as serious or, in the worst case, fatal injuries can occur in the event of a fall. Without a fall protection solution, the machine may no longer be set up or maintained. There is a risk of decommissioning.

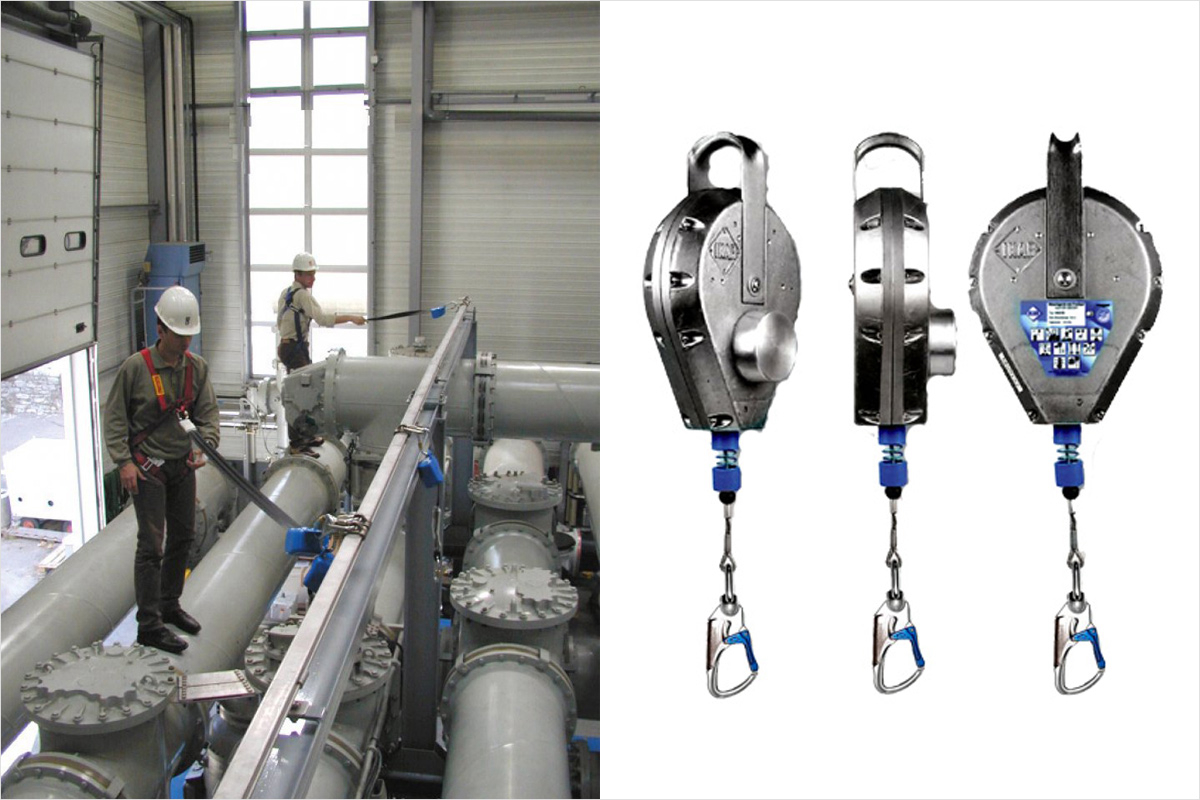

Unfortunately, there is no standard system on the market that can be used for all machine types. In this respect, an individual feasibility study of a solution is required for each machine. This means that the situation on site must always be checked. To prevent the risk of falling, it is necessary to install a fall protection system on both sides of the die casting machine (ejector and inlet side). In order to realise this, the statics of the machine must be checked to see whether the forces introduced in the event of a fall can be absorbed. The next step is to determine the type and position of the fall protection. In the case of the die-casting machines at the Daimler plant in Esslingen-Mettingen, the solution consisted of a multirail system on the ejector side and one or two DAVIT arms on the inlet sides. The systems are each operated with a fall arrester with abseiling function. This is intended to prevent the casualty from getting caught in front of the hot mould plates and being lowered into the machine bed.

All persons who set up or maintain machines and thus enter an area where there is a risk of falling

Fundamentally, the safety of employees should be a priority for every operator/company. Accidental employees cause costs that can be avoided. As part of a risk assessment, it can be determined that the machine in question may no longer be operated for safety reasons and may have to be shut down.

Are there any legal regulations that require PPE to be worn on a die casting machine?

The European Directive 89/656/EEC deals with personal protective equipment (PPE). It is particularly aimed at the use of PPE at work. This directive addresses the correct conditions of use for PPE and the role it plays in improving health and safety conditions in the workplace. According to this directive, PPE is defined as: "...any equipment intended to be worn or used by the user to protect him/her from one or more hazards that may threaten his/her safety or health at work. There are also country-specific rules and regulations. In Germany, the DGUV Rule 112-198 (previously BGR 198) is authoritative". However, collective protective measures always have absolute priority. The use of PPE is seen as a last resort and is only permitted if the installation of railings, scaffolding or the use of lifting platforms etc. is not possible or involves too much effort.