Regular maintenance is the only way to ensure that ferries operate safely and that no personal injury occurs due to defects, material or other faults. However, the safety aspect is also of the utmost importance in the maintenance processes themselves. Service technicians who are entrusted with maintenance on ferries must be protected against falls and other accident scenarios by appropriate safety equipment. The regulations of the DGUV (German Social Accident Insurance) also provide a legal framework for this.

At the same time, many companies want maintenance to be carried out as quickly and efficiently as possible. Making both possible can be a challenge, especially in view of the exposed installation situation on ships. So how can high safety standards and maximum efficiency be combined?To ensure that a ferry can be used in compliance with the highest safety standards, various aids are required, with electronic monitoring and measuring systems such as GPS, echo sounder and radio being among the most important components. However, all these systems are usually located on masts that are difficult for service technicians to access. For this reason, maintenance is often carried out as part of a shore inspection. However, the "inspection on slipway" must be accompanied by a recognised expert for shipbuilding or shore inspections. Alternatively, scaffolding must be erected on the ship for the purpose of maintenance.

This means that maintenance and any repair work takes up a relatively large amount of time and effort. And this in turn can lead to high costs, because apart from the expenses for maintenance and modernisation work, the ferry concerned is of course not usable for a certain period of time, which means that calculated income is lost. In order to simplify maintenance and thus make it more (cost-)efficient, it would make sense to improve access to the facilities. Maintenance personnel can then reach the installations more safely and are no longer solely reliant on ladder constructions as a solution.

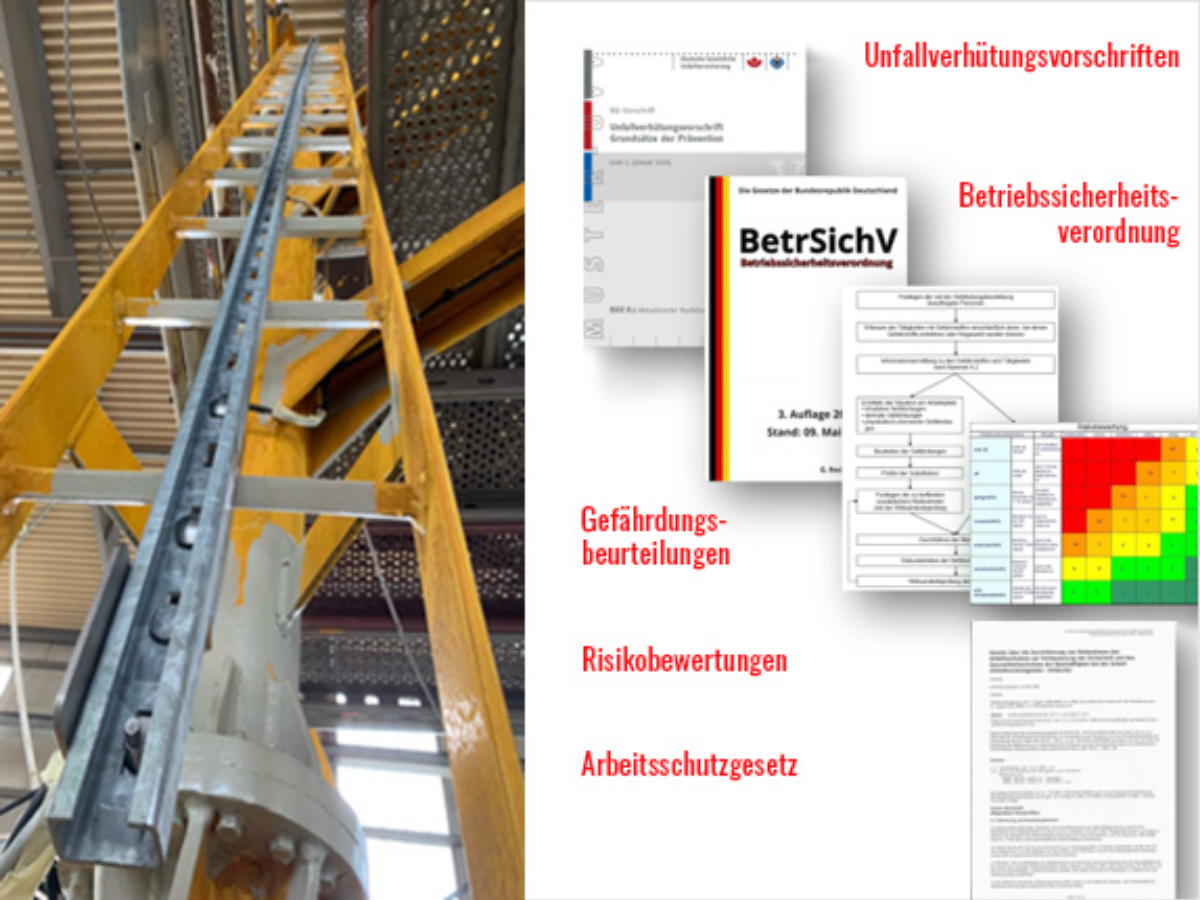

Step 1: Checking the existing parameters The first step is to compile all documents that contain important aspects of the risk assessment as well as all necessary standards and regulations. This is necessary not least because different criteria apply when working on fixed ladders and ships than for corresponding activities on land. For example, it is permitted to use fixed ladders with square rungs when working on board a ship, whereas such use is not permitted on land. Important: All the information that has been compiled should be considered taking into account the exposed installation situation of the ferry. This is the only way to achieve real added value with regard to the maintenance of personal safety equipment on board.

Step 2: Selecting the system and adapting it to the installation conditions To ensure that the service technicians tasked with maintenance and repair work can access all relevant equipment on the ferry easily and safely, the installation of a rail system with runners is a good option. SKYLOTEC's designs offer particularly good conditions for flexible, convenient and efficient maintenance work. However, it should be noted that a customised solution must be developed in collaboration with the manufacturer, as there is no standard solution that is equally suitable for all ferries when it comes to a suitable rail system. When designing and implementing the system, it is important to comply with all legal standards.

Step 3: Acceptance of the system and on-site user training Once all systems have been properly installed and all required labelling has been created, the work is approved by a recognised expert. All persons working on the ferry are then given in-depth training to familiarise them with the use of the safety systems. It is also advisable to familiarise them with the newly configured or adapted rescue concept. Practical experience has shown that the installation of a rail system for maintenance work has actually led to increased safety for personnel and provided a noticeable increase in terms of flexibility and efficiency. For example, after successfully trialling the first installed rail, one customer has retrofitted all of its ferries accordingly.

The SKYRAIL traversable rail system, developed by the renowned manufacturer SKYLOTEC, offers reliable fall protection that enables more flexible working, especially for maintenance work at height. Thanks to various connecting and curved elements, the system can be easily adapted to different working environments and proves to be an effective aid, not least in areas that are difficult to access. A special runner is also installed so that the service technicians can move along the rail. The entire system is relatively quick to install and requires relatively few brackets due to the large fixing distances, which is why the installation costs are low. In addition, the rail is insensitive to signs of wear.

Detailed occupational health and safety measures relating to maintenance on ferries can be found in DGUV Rule 109-603 (Shipbuilding sector). The DGUV is the publisher of the document, which is freely available online.

The exact costs for the entire retrofit, including planning, depend on the spatial conditions of the ferry. The size of the ship in particular is a decisive factor. As the rail systems are also customised, it is not possible to put a general figure on the costs. However, installation is relatively easy, which is why the costs are kept within reasonable limits. We can provide you with details of the price during a consultation when we discuss all the details of your project.