Are you responsible for low-loaders, lorries or other transport vehicles? As a haulier, vehicle manufacturer or building contractor, do you occasionally or constantly have to transport loads of any kind? Or do you normally use your construction site lorries for excavation and gravel transport and are rarely on the road with a low-loader or only occasionally transport general cargo on the flatbed? In all these cases, the aim of every contractor and driver must be to avoid accidents, high costs and possible legal disputes. Experience shows that the strength of the lashing equipment used is often overestimated and the forces that occur during driving are often underestimated. The aim should therefore always be to counter recklessness and ignorance of physical and legal contexts with sound basic knowledge.

Important to know: The StVO and the DGUV "Fahrzeuge" are not only aimed at the driver and owner of the vehicle, but also at anyone who is responsible for the proper loading of vehicles. The regulations for every transport operation stipulate that the load, lashing chains, equipment and other loading equipment must be stowed safely and secured against falling and avoidable noise. For you, this means that you must secure the load in such a way that it cannot slip. Reports in the media, pictures of accidents and traffic reports about overturned vehicles or lost loads show that this is not only possible with light loads. We therefore urgently warn against securing loads "by feel": Physics incorruptibly follows its own laws. The forces actually acting on the loading area can only be controlled on the basis of specific calculations.

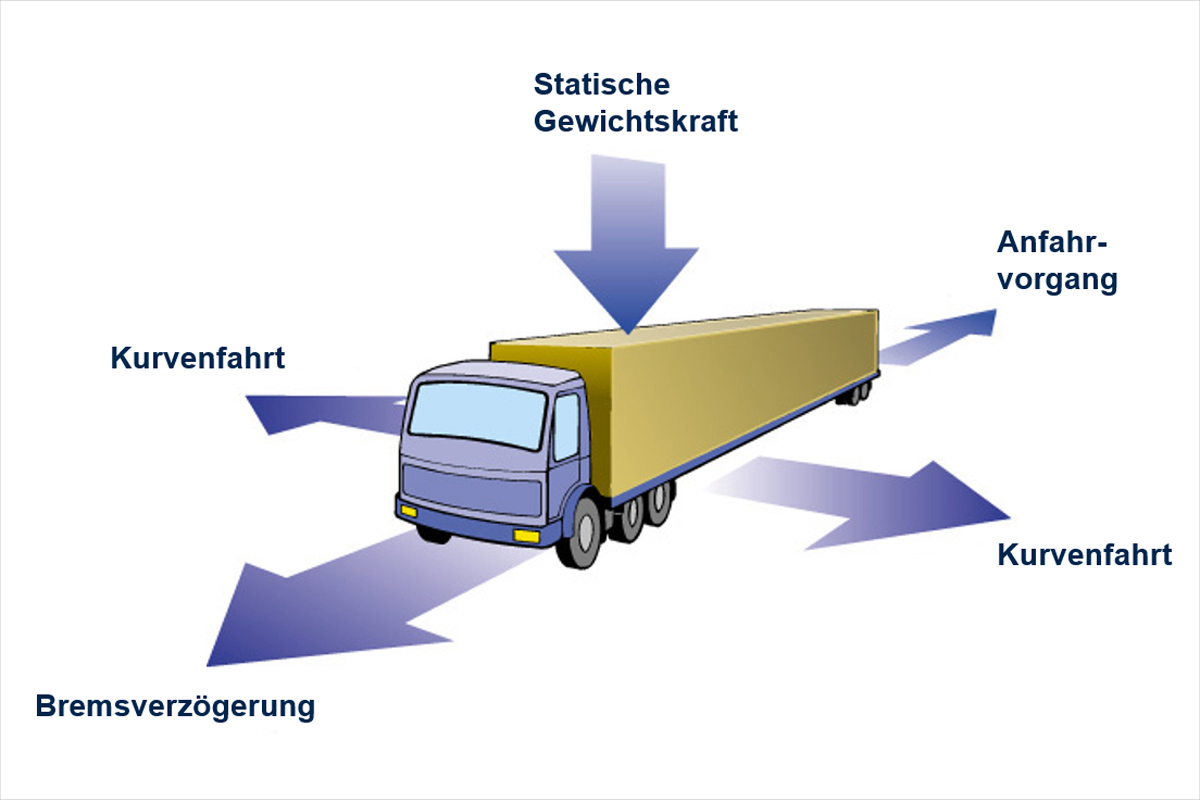

As a general rule, 0.8 times the weight of the load pushes in the direction of the driver's cab during full braking (including travelling downhill) and half the weight of the load pushes in the direction of the side walls when cornering and starting off. Expressed in figures using an example, this means that with a load mass of m = 10,000 kg, 8,000 kg ≈ 8,000 daN push in the direction of the driver's cab. When moving off and cornering, 5,000 kg ≈ 5,000 daN press against the dropside. Appropriate lashing equipment must hold these forces securely. There are basically two possible types of lashing: tie-down lashing on the one hand and direct lashing on the other, which is further subdivided into diagonal lashing and diagonal lashing. Corresponding calculations can be found in VDI Guideline 2700-2 "Lashing forces" or DIN EN 12195-1.

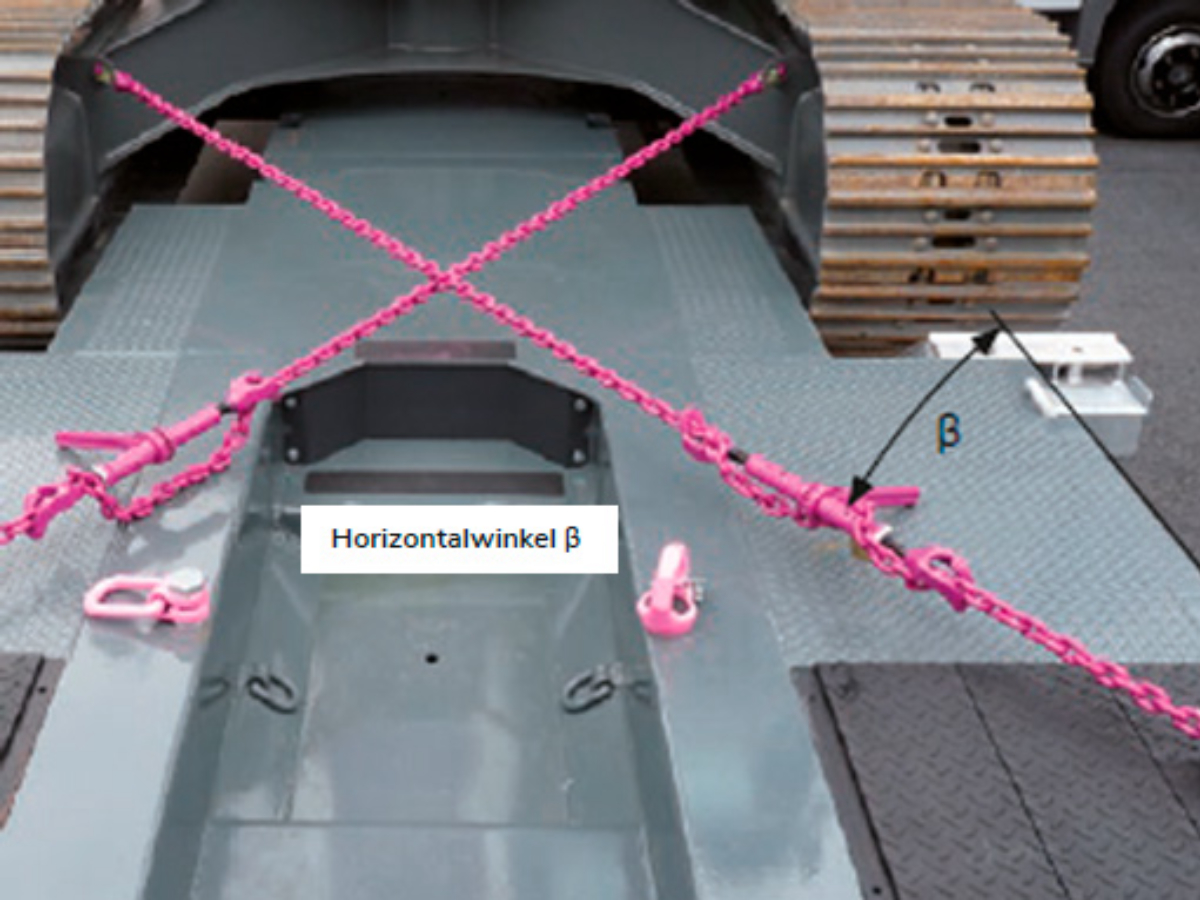

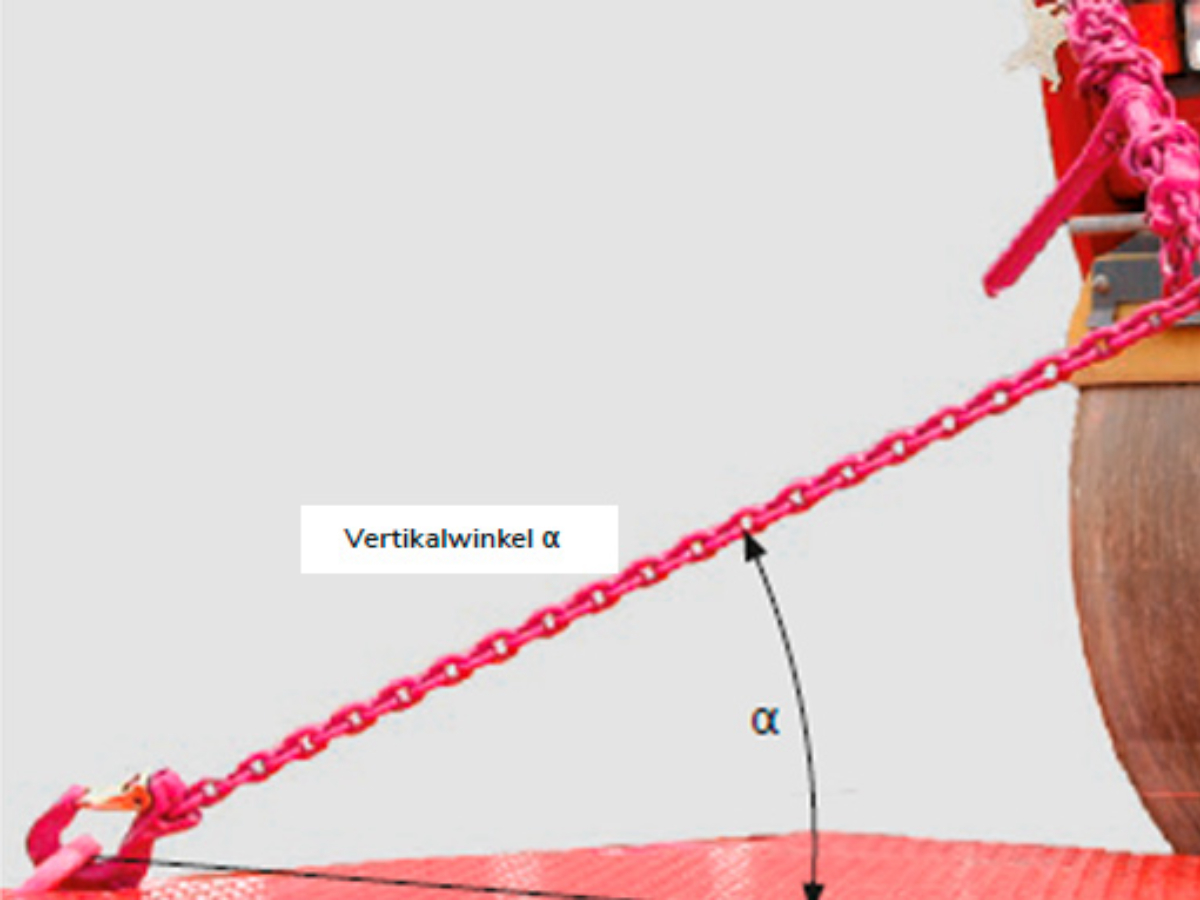

One of the biggest challenges when securing heavy loads is to avoid so-called static overdetermination. The problem in plain language: If you use more than two lashing devices per direction when lashing directly, only two of the lashing devices used will still absorb the entire force - or at least the majority of it. In theory, more than two strands can carry the load if all the strands fulfil the following boundary conditions: equal strand lengths equal lashing angles equal pre-tensions equal lashing equipment (elongations) However, practitioners know that securing loads in this way is not feasible. You can solve this problem with a trick: redirect the lashing chains so that they lead from the load to the vehicle in two strands. The result is four load-bearing strands in one direction. However, the deflection must result in an equalisation of forces in the double strands. You can achieve this, for example, by deflecting around a round lifting bollard, as shown in the two pictures above. An even better equalisation of forces can be achieved with VIP lashing chains with a deflection roller. As this "double lashing" requires you to take other angles into account in addition to the conventional lashing angles α and β, as well as case-specific boundary conditions, you cannot calculate this type of load securing in the conventional way.

A customer was faced with the challenge of having to transport a heavy load for a 15-tonne low-loader. No standardised lashing point was attached to the load itself. The lashing chains planned for securing the load had to be as ergonomic as possible, as light as possible and also theft-proof. The necessary lashing points for the transport vehicle were also required. After an intensive assessment of the on-site situation and in consultation with the Carl Stahl specialist consultant, the solution for the transport vehicle was RUD lashing points type LPW 13,400 daN HV12+4. For the missing lashing points on the transported goods, RUD ICE crane chains were built as lashing points. RUD ICE-VSK-Curt SL nominal thickness 10 mm were used for lashing.

Buy RUD lashing points

Buy RUD ICE lashing chains

In addition to grade 8, 10 and 12 lashing chains, there are also so-called heavy-duty lashing straps that are suitable for heavy-duty transport.

In addition to the classic lashing equipment and lashing points, an anti-slip mat and edge protectors should be used for the load.

Yes, there are. Carl Stahl's product range also includes textile lashing chains made from a high-strength Dyneema® fibre. These chains are up to 8 times lighter than a comparable chain made of steel.

Where can I get more specialised information on the subject of load securing?The Carl Stahl consultants will be happy to visit you on site and advise you on your specific load securing requirements. In addition, Carl Stahl offers a training course entitled "The basics of load securing" as part of its specialist seminars.